A post hole digger gearbox is a vital component of post hole diggers, commonly used in agriculture, construction, and landscaping to create holes for fencing, planting, and other purposes. The gearbox plays a crucial role in transferring power from the digger's engine to the auger bit, allowing for efficient digging. To understand how this gearbox functions, it's essential to examine its key components:

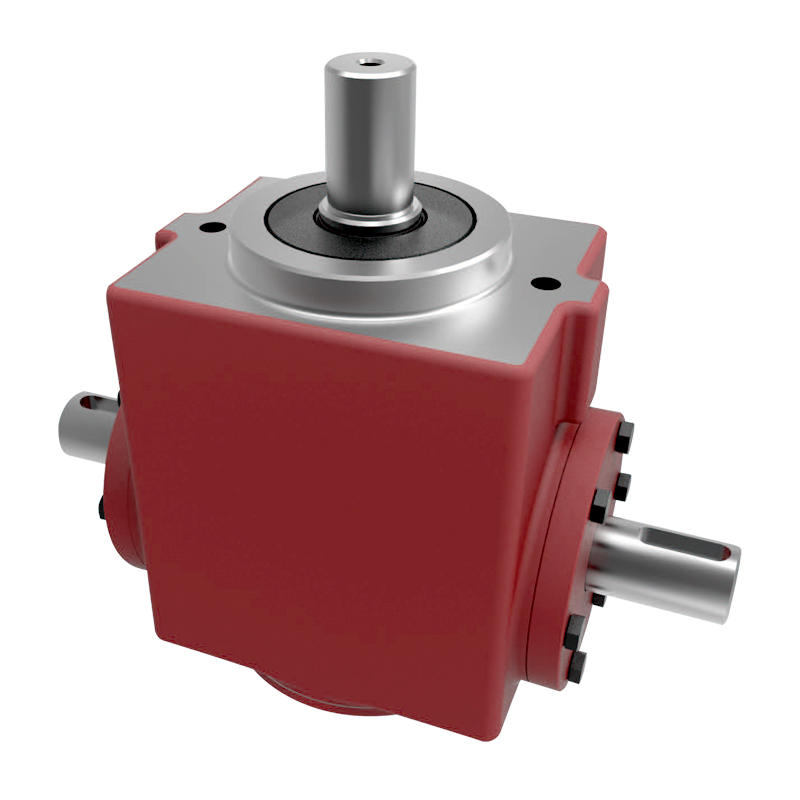

1. Input Shaft:

The input shaft is the part of the gearbox that receives power from the engine or power source. It typically connects to the engine's output shaft or a power take-off (PTO) shaft. The rotational force generated by the engine is transmitted to the input shaft, initiating the digging process.

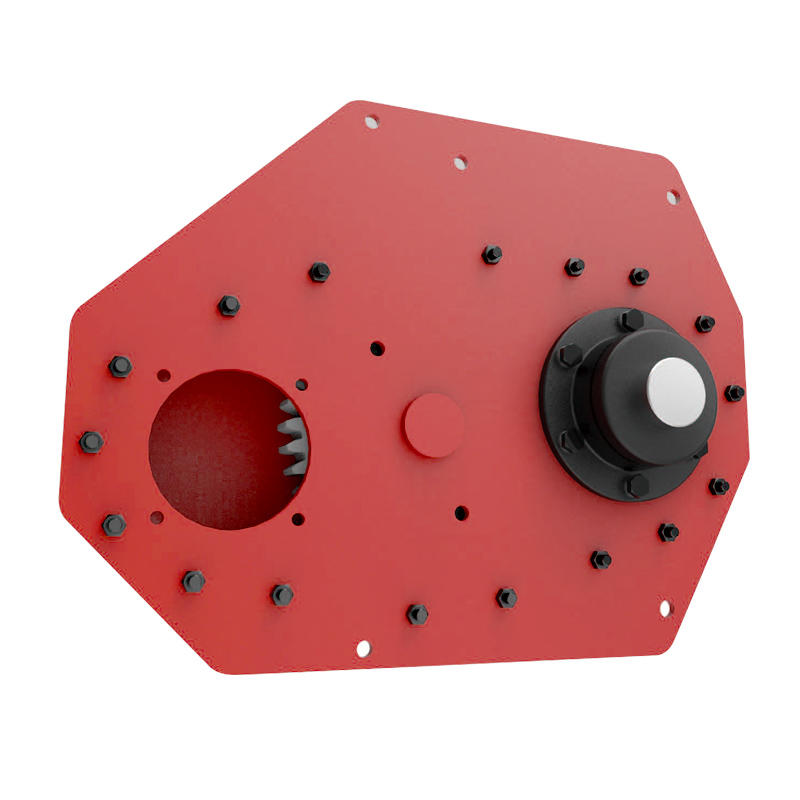

2. Gears:

Gears are at the heart of any gearbox. In a post hole digger gearbox, you will find various gears, including the pinion gear and spur gears. These gears work together to transmit and control the rotational motion of the input shaft, ensuring it is transferred to the auger bit at the desired speed and torque.

3. Output Shaft:

The output shaft extends from the gearbox and connects to the auger bit. It's responsible for transmitting the rotational motion and torque generated by the gears to the auger. The output shaft's design and strength are critical to ensure it can handle the demands of drilling into various types of soil and terrain.

4. Housing:

The housing encases and protects the gearbox's internal components. It is typically made of sturdy materials, such as cast iron or steel, to withstand the forces and stresses associated with digging. The housing also contains lubricants to keep the gears properly lubricated for smooth operation.

5. Bearings:

Bearings support the rotating shafts and gears within the gearbox. They reduce friction, allowing for efficient power transmission and preventing premature wear of moving parts. Properly maintained bearings are essential for the gearbox's longevity and performance.

6. Seals:

Seals are used to prevent dust, dirt, water, and other contaminants from entering the gearbox while retaining the lubricating oil inside. They help maintain the gearbox's integrity and protect its internal components from damage.

7. Lubrication System:

A lubrication system ensures that all moving parts within the gearbox receive adequate lubrication to reduce friction, heat generation, and wear. It typically consists of oil reservoirs, oil pumps, and distribution channels that deliver lubricating oil to critical areas.

8. Gear Shifting Mechanism (Optional):

Some post hole digger gearboxes may include a gear shifting mechanism that allows operators to change the rotational speed and torque of the auger bit. This feature is useful when adapting to different soil conditions or hole diameters.

9. Output Flange or Connection Point:

The output flange or connection point is where the auger bit is attached to the gearbox. It must be secure and well-designed to ensure a reliable connection that can withstand the forces exerted during digging.

10. Safety Features (Optional):

In some models, safety features may be incorporated into the gearbox design. These can include emergency shut-off mechanisms or overload protection systems to safeguard the operator and prevent equipment damage in the event of a jam or overload.

These components include the input shaft, gears, output shaft, housing, bearings, seals, lubrication system, gear shifting mechanism (if applicable), output flange or connection point, and optional safety features. Proper maintenance and care of these components are crucial to ensure the longevity and reliable performance of a post hole digger gearbox, ultimately contributing to efficient and effective hole digging in various applications.

English

English 中文简体

中文简体 Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)