Gears are the unsung heroes of the mechanical world, silently working their magic in a vast array of machines, from bicycles to automobiles, and even the most complex industrial equipment. Among the many places you'll find gears, one of the most critical applications is in gear box transmissions. Gear box gears are the backbone of these systems, enabling the controlled transfer of power, speed, and torque.

Understanding Gear Box Gears:

Gear box gears, simply put, are toothed wheels that mesh together to transmit power from one shaft to another. They are available in various shapes and sizes, each designed for specific applications. The primary types of gear box gears include:

1. Spur Gears: Spur gears are the most common type and consist of cylindrical wheels with teeth parallel to the gear's axis. They are simple, efficient, and provide precise speed and torque ratios. Spur gears are often used in applications where noise is not a concern, such as industrial machinery.

2. Helical Gears: Helical gears have angled teeth that create a helix pattern along the gear's face. This design offers smoother operation and increased load-carrying capacity compared to spur gears. Helical gears are commonly found in automotive transmissions.

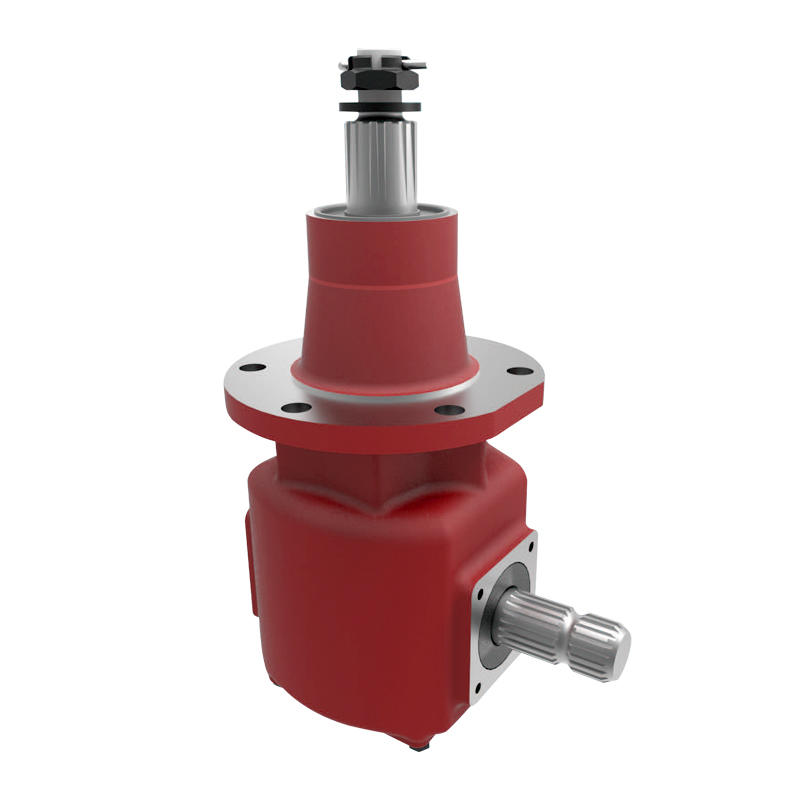

3. Bevel Gears: Bevel gears are cone-shaped and used to transmit power between shafts that intersect at an angle. They are ideal for changing the direction of power transmission in applications like differential gears in automobiles.

4. Worm Gears: Worm gears consist of a threaded worm (a cylindrical shaft with a spiral groove) and a mating gear. They provide high gear reduction ratios and are often used in applications where self-locking and high torque are required, such as in winches and conveyor systems.

5. Planetary Gears: Planetary gears, also known as epicyclic or sun-and-planet gears, are a set of gears arranged in a planetary configuration. They offer versatility and are commonly used in automatic transmissions and robotics.

The Role of Gear Box Gears in Transmissions:

Gear box gears play several crucial roles in transmissions:

1. Speed Reduction and Increase: By meshing gears of different sizes, gear box gears can either reduce or increase the rotational speed of the output shaft relative to the input shaft. This feature allows machines to operate at the desired speed for a particular task.

2. Torque Multiplication: Gears enable the multiplication of torque, especially in situations where high torque is required to overcome resistance or lift heavy loads. The gear ratio determines the extent of torque multiplication.

3. Directional Control: Gears can change the direction of power transmission. For instance, in an automotive transmission, gears are used to shift between forward and reverse modes.

4. Power Distribution: Gear box gears distribute power evenly among multiple shafts, ensuring that each component receives the necessary energy to perform its function. This is crucial in systems like automatic transmissions, where power needs to be distributed to various components.

5. Synchronization: In manual transmissions, gear box gears synchronize the speed of the input and output shafts to allow for smooth gear changes without grinding.

6. Load Distribution: Gears distribute loads evenly across their teeth, minimizing wear and tear on individual gear components. Proper load distribution contributes to the longevity of gear box gears.

Transmission and Gears: A Symbiotic Relationship:

The relationship between transmissions and gears is symbiotic. Transmissions require gears to function effectively, and gears, in turn, rely on transmissions to deliver power where it's needed. Transmissions, such as those found in automobiles, are responsible for selecting the appropriate gear ratio based on driving conditions, engine power, and the desired speed.

Gear box gears are carefully engineered to mesh precisely, ensuring efficient power transfer and minimal energy loss due to friction and heat. The selection of the right gear at the right time is critical for achieving optimal vehicle performance and fuel efficiency. In automatic transmissions, complex hydraulic and electronic systems work in tandem with gear box gears to seamlessly shift between gears, providing smooth acceleration and deceleration.

In industrial applications, gear box gears enable heavy machinery to operate smoothly and efficiently. Whether it's a conveyor system in a factory, a crane at a construction site, or a wind turbine on a hillside, gear box gears ensure that power is delivered reliably and precisely to perform specific tasks.

Understanding the mechanics of gear box gears and their interaction with transmissions is key to appreciating their indispensable contribution to the modern world of machinery and transportation.

English

English 中文简体

中文简体 Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)