Gearboxes serve as the unsung heroes behind the seamless transfer of power and motion in various industries. Understanding the intricacies of their functioning, components, and applications across automotive, industrial machinery, aerospace, and beyond is essential to appreciate their significance in driving efficiency and innovation.

Working Principles of Gearboxes: At the heart of gearboxes lies the interaction of meticulously designed gears that form gear trains. By meshing gears of different sizes and configurations, gearboxes achieve specific gear ratios to modify speed and torque efficiently. This transformation of rotational energy enables gearboxes to meet diverse application requirements with precision and reliability.

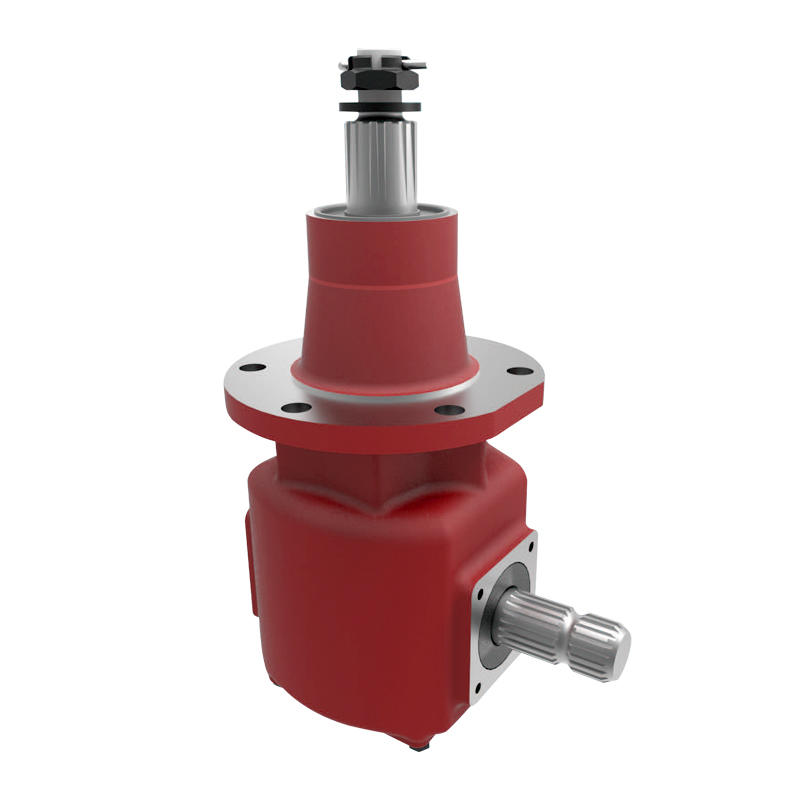

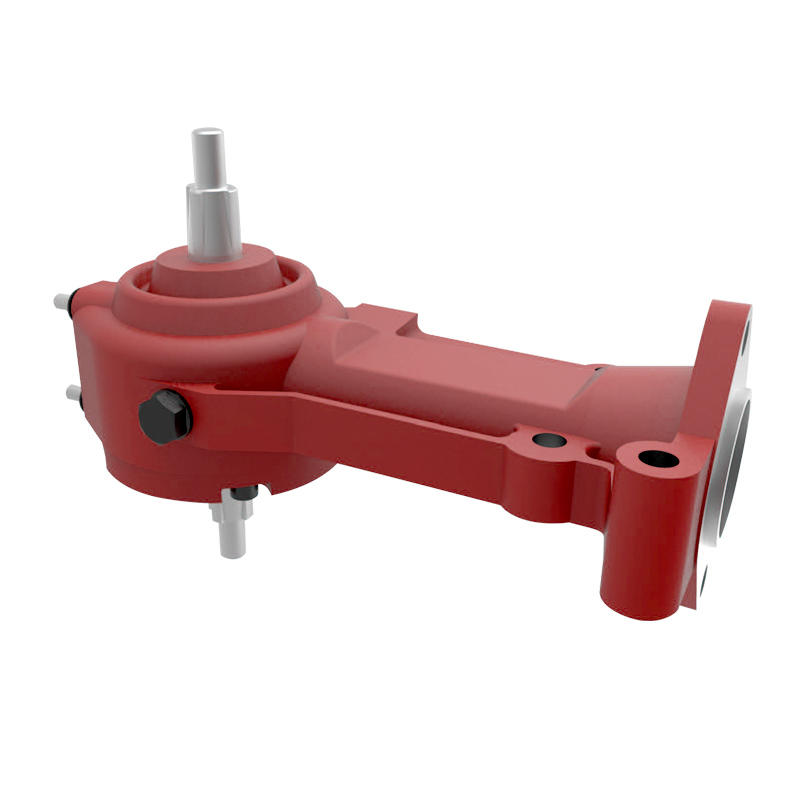

Components of Gearboxes: Gears stand as the backbone of gearboxes, engaging with one another to transmit motion and regulate speed and torque. Shafts provide support and linkage for the gears, ensuring seamless power transmission, while bearings reduce friction and promote smooth rotation. The gearbox housing encases and safeguards these internal components, with the lubrication system and seals enhancing operational longevity and performance.

Functions of Gearboxes: Gearboxes excel at altering speed and torque outputs to match the unique demands of different applications. Whether increasing torque while reducing speed or vice versa, gearboxes deliver the necessary power adjustments. Moreover, they offer the flexibility to reverse rotation direction, provide mechanical advantage, and shield equipment from overload conditions, contributing to operational stability and durability.

Applications of Gearboxes: In the automotive realm, gearboxes are integral to vehicle transmissions, enabling seamless gear shifting and enhancing fuel efficiency. Industrial machinery leverages gearboxes in conveyor systems, manufacturing processes, and material handling equipment to regulate speed and torque effectively. Aerospace industries rely on gearboxes for aircraft engines, rotor systems, and landing gear mechanisms, ensuring safe and efficient operations.

Automotive Industry: In the automotive sector, gearboxes are pivotal components within transmissions, featuring a series of gears that facilitate shifting between different speeds. By carefully selecting gear ratios, gearboxes optimize engine performance, enhance fuel efficiency, and provide the necessary power for vehicle propulsion. Whether manual or automatic, gearboxes tailor the power delivery to meet the dynamic demands of driving conditions, showcasing their versatility and precision in the automotive landscape.

Industrial Machinery: Industrial machinery benefits greatly from gearboxes, which regulate speed and torque in various applications to enhance productivity and operational efficiency. In conveyor systems, gearboxes control the movement of materials along production lines, ensuring smooth and consistent workflow. Moreover, gearboxes in manufacturing equipment enable precise control over machining processes, facilitating accurate production and quality standards. From material handling to assembly operations, gearboxes play a pivotal role in driving industrial machinery forward with good performance and reliability.

Aerospace Sector: In the aerospace industry, gearboxes are essential components in aircraft engines, rotor systems, and landing gear mechanisms. Gearboxes in aircraft engines convert the high-speed rotation of the turbine into the appropriate speed and power for propulsion, driving the aircraft forward with efficiency and reliability. Rotor systems rely on gearboxes to transmit power from the engine to the rotor blades, enabling precise control over lift and maneuverability. Additionally, gearboxes in landing gear mechanisms facilitate smooth and controlled landings, ensuring the safety and functionality of aircraft operations.

Conclusion: Gearboxes serve as the cornerstone of motion control and power transmission across automotive, industrial machinery, aerospace, and various other industries. Understanding the technical intricacies, components, and diverse applications of gearboxes is essential for professionals seeking to optimize performance and efficiency in their respective fields. With their ability to alter speed, torque, and direction, gearboxes empower industries to achieve precision, reliability, and operational excellence, propelling advancements and innovations in the ever-evolving world of technology and engineering.

English

English 中文简体

中文简体 Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)