China High Quality Mixer Machine Gearbox Producer Wholesaler

In the symphony of industrial efficiency, there exists a crucial component that often operates behind the scenes yet drives the rhythm of productivity the mixer machine gearbox.

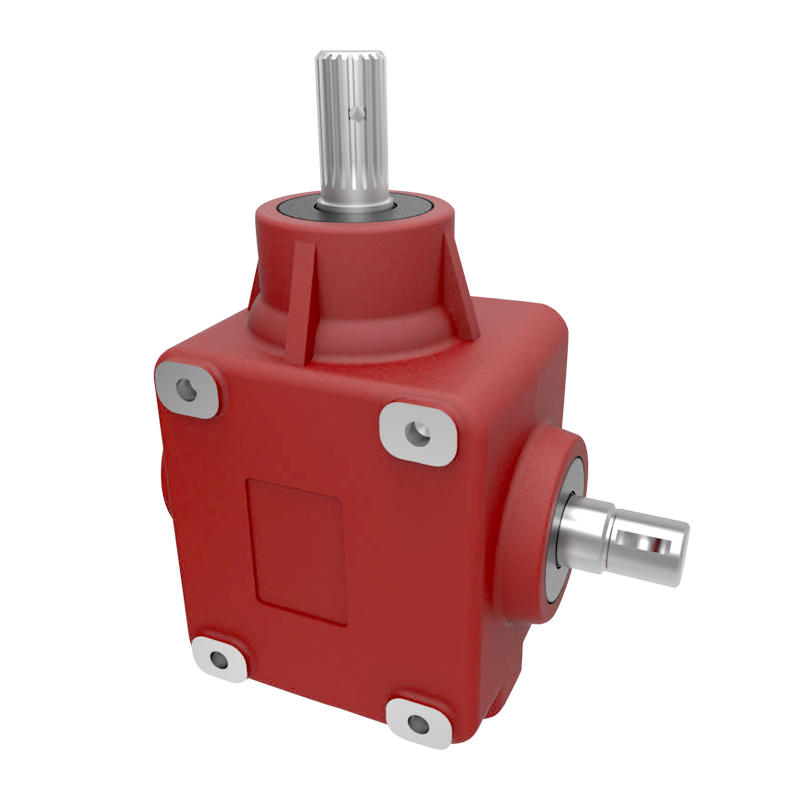

At its core, a mixer machine gearbox is a complex assembly of gears, shafts, and bearings meticulously engineered to transmit power efficiently and reliably. The Mixer machine gearbox's primary function is to regulate the speed and torque of the mixer's shaft, enabling precise control over the mixing process. One of the key advantages of a mixer machine gearbox lies in its versatility. Designed to accommodate a wide range of mixing applications, the mixer machine gearbox can adapt to varying viscosity, density, and volume requirements.

In addition to versatility, reliability is another hallmark of the mixer machine gearbox. Advancements in gearbox technology have led to innovations that enhance efficiency and sustainability. By optimizing gear design and implementing lubrication systems, modern mixer machine gearboxes operate with greater energy efficiency, reducing power consumption and environmental impact. Mixer machine gearbox not only benefits the bottom line but also aligns with the growing emphasis on eco-friendly manufacturing practices. With interchangeable gear sets and adjustable speed ratios, operators can fine-tune the mixing parameters to meet specific production demands, whether it involves blending delicate ingredients or processing high-viscosity fluids.

Despite its robustness and sophistication, the mixer machine gearbox is not immune to challenges. Extreme operating conditions, such as high temperatures or corrosive environments, can pose threats to gearbox integrity. The mixer machine gearbox stands as a testament to the ingenuity and engineering prowess of the industrial sector. As we navigate the ever-evolving landscape of manufacturing, the heartbeat of industrial efficiency resonates through the rhythmic hum of the mixer machine gearbox.

In the world of machinery, where precision and efficiency are paramount, the mixer gearbox stands as a testament to innovation and engineering prowess. As a vital component in various industries such as manufacturing, construction, and food processing, the mixer gearbox plays a pivotal role in ensuring seamless operation and performance.

At its core, the mixer gearbox serves as a power transmission device, transferring rotational energy from the motor to the mixing mechanism. One of the key features of mixer gearboxes is their versatility. Efficiency is a hallmark of modern mixer gearboxes. The durability of mixer gearboxes is another critical aspect that cannot be overlooked. Operating in demanding environments with exposure to harsh conditions, these components must withstand constant wear and tear without compromising performance. Robust materials, advanced lubrication systems, and stringent quality control measures ensure that mixer gearboxes maintain their functionality over extended periods of use.

The advent of smart technologies has changed gearbox monitoring and maintenance. Integrated sensors and diagnostic systems enable real-time performance monitoring, allowing operators to detect potential issues before they escalate into costly failures. Predictive maintenance algorithms analyze data trends to schedule maintenance activities proactively, reduce uptime and prolong gearbox lifespan.

In addition to their mechanical prowess, mixer gearboxes often incorporate advanced technologies to enhance their capabilities further. These innovations reflect the ongoing evolution of mixer gearbox design to meet the evolving needs of modern industries. Maintenance plays a crucial role in prolonging the lifespan of mixer gearboxes and ensuring uninterrupted operation. Many manufacturers provide comprehensive maintenance guidelines and support services to assist operators in keeping their gearboxes in condition.

English

English 中文简体

中文简体 Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)