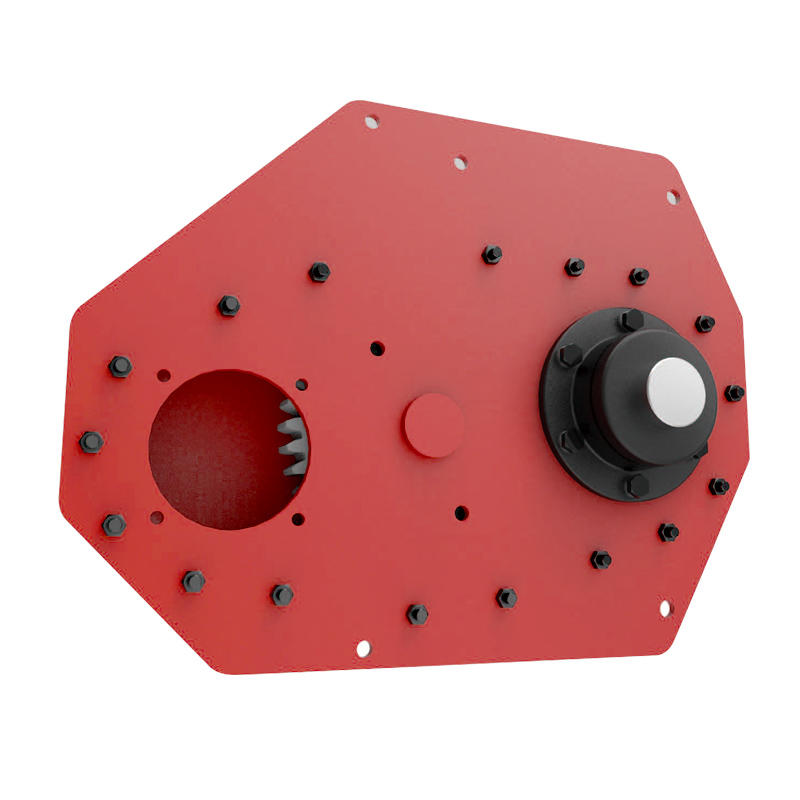

Design Supply Reduction Gearbox Manufacturers Supplier For Sale

Reduction gearbox manufacturers are the backbone of industries requiring precision transmission of mechanical power. These manufacturers specialize in creating gearboxes that reduce the speed of a prime mover while increasing torque, a critical function in various mechanical applications.

One of the standout features of reduction gearbox manufacturers is their commitment to innovation. These manufacturers are constantly researching and developing new technologies to improve the efficiency and reliability of their products. They invest heavily in research and development, which allows them to maintain a strong position and provide cutting-edge solutions to their customers.

Another key feature of reduction gearbox manufacturers is their focus on customization. Understanding that no two applications are the same, these manufacturers offer a wide range of standard products and also provide custom solutions tailored to the specific needs of their clients. This ability to customize is a significant advantage for customers who require unique solutions that are not available off the shelf.

Quality is a non-negotiable aspect for reduction gearbox manufacturers. They adhere to stringent quality control measures at every stage of the manufacturing process. From the selection of raw materials to the final assembly, each component is meticulously inspected to ensure it meete higher standards. This commitment to quality is evident in the longevity and performance of the gearboxes they produce.

Reduction gearbox manufacturers also pride themselves on their technical expertise. They employ teams of skilled engineers and technicians who have a deep understanding of the mechanical principles and engineering challenges involved in gearbox design and manufacturing. This expertise allows them to provide not just products, but also valuable technical support and咨询服务 (consultation services) to their customers.

The manufacturing process itself is another distinguishing feature of reduction gearbox manufacturers. They utilize machinery and advanced manufacturing techniques to produce gearboxes with good precision and accuracy. This level of sophistication in the manufacturing process ensures that the final product is of higher quality and performs reliably under demanding conditions.

After-sales service is also a critical feature that sets reduction gearbox manufacturers apart. They recognize the importance of supporting their customers even after the sale is complete. This is why they offer comprehensive after-sales services, including installation assistance, maintenance, and repair services. They also provide training to help customers get the most out of their gearboxes and ensure they are used correctly and efficiently.

Sustainability is becoming an increasingly important feature for reduction gearbox manufacturers. They are aware of the environmental impact of their operations and are taking steps to minimize their carbon footprint. This includes using energy-efficient manufacturing processes, recycling materials, and designing gearboxes that are more energy-efficient to operate.

The global reach of reduction gearbox manufacturers is a testament to their ability to serve a diverse range of customers across different industries and regions. They have established a strong network of distributors and service centers worldwide, ensuring that their products and services are accessible to customers no matter where they are located.

Reduction gearbox manufacturers are characterized by their innovative approach, customization capabilities, commitment to quality, technical expertise, advanced manufacturing processes, comprehensive after-sales services, focus on sustainability, and global presence. These features collectively contribute to their ability to provide high-performance gearbox solutions that meet the diverse needs of customers across various industries. As the demand for reliable and efficient power transmission systems continues to grow, the role of reduction gearbox manufacturers will remain pivotal in driving progress and innovation in mechanical engineering.

English

English 中文简体

中文简体 Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)