Wholesale Fertilizer Spreader Gearboxes Agricultural Gearboxes Factory

In the intricate machinery of modern agriculture, the fertilizer spreader gearbox stands as a critical component that ensures the efficient and precise application of vital nutrients to crops. This article delves into the essential role of fertilizer spreader gearboxes within the agricultural sector, highlighting their design, functionality, and the pivotal part they play in enhancing crop yields and sustainability.

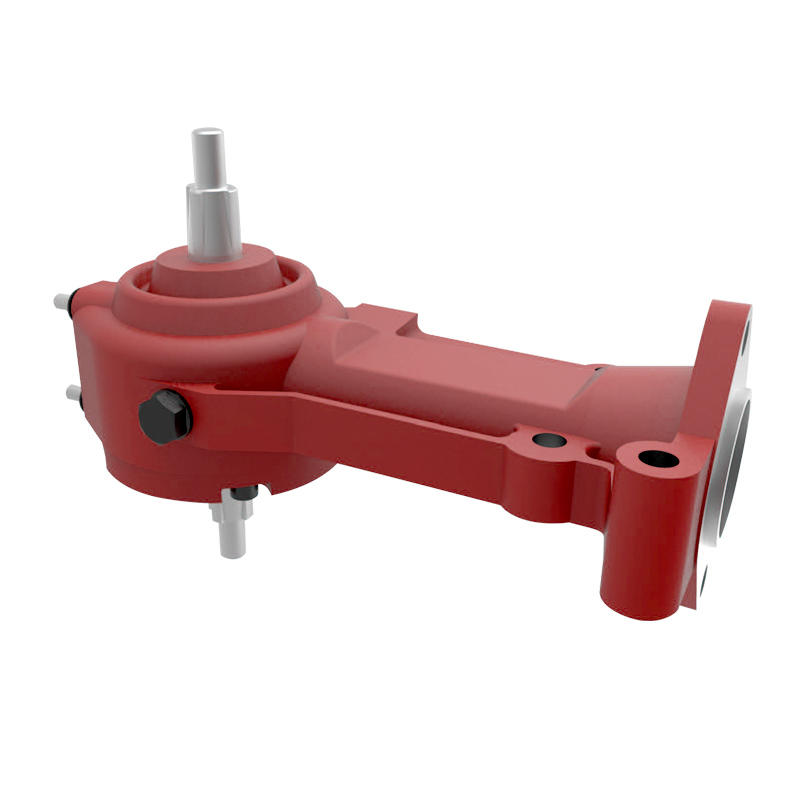

The fertilizer spreader gearbox is a sophisticated piece of engineering that lies at the heart of fertilizer spreader machines. These machines are designed to distribute fertilizers evenly across vast fields, ensuring that each plant receives the necessary nutrients for ideal growth. The gearbox, as the name implies, is responsible for transmitting the power from the spreader's engine to the spreading mechanism, which typically includes rotating discs or beaters. By adjusting the speed and torque of this transmission, the fertilizer spreader gearbox allows for the precise control of fertilizer application rates, which is crucial for maintaining soil fertility and crop health.

The importance of fertilizer spreader gearboxes cannot be overstated, as they directly impact the efficiency and effectiveness of fertilizer distribution. A well-designed gearbox ensures that the fertilizer is spread uniformly, minimizing waste and preventing over-fertilization, which can contribute to environmental pollution and economic losses. The precision afforded by a reliable gearbox also means that farmers can tailor their fertilizer application to the specific needs of different crops and soil types, optimizing their agricultural practices for utilizing yield and quality.

In the context of sustainable agriculture, fertilizer spreader gearboxes are instrumental in reducing the environmental footprint of farming operations. By facilitating accurate and controlled fertilizer application, these gearboxes help to minimize the runoff of nutrients into water bodies, which can cause eutrophication and harm aquatic ecosystems. Moreover, the efficient use of fertilizers enabled by high-quality gearboxes reduces the demand for chemical inputs, contributing to a more eco-friendly and cost-effective farming approach.

The design of fertilizer spreader gearboxes is a balance between durability, efficiency, and ease of maintenance. Agricultural environments are often harsh and demanding, with machines operating under heavy loads and challenging conditions. Therefore, gearboxes must be constructed from robust materials that can withstand the rigors of continuous operation. The use of high-grade steel, coupled with advanced manufacturing techniques, ensures that fertilizer spreader gearboxes can endure the stresses of agricultural work, providing long-lasting performance and reliability.

Efficiency is another key consideration in the design of fertilizer spreader gearboxes. The gearbox must convert the engine's power into the rotational motion of the spreading mechanism with minimal energy loss. This is achieved through the careful selection of gear ratios and the incorporation of efficient bearings and seals. An efficient gearbox not only contributes to lower fuel consumption but also extends the life of the spreader's engine, reducing overall operational costs for farmers.

Maintenance is a critical aspect of ensuring the longevity and outstanding performance of fertilizer spreader gearboxes. Regular inspection and servicing are necessary to identify and address any wear and tear, lubrication issues, or alignment problems. Manufacturers often provide detailed maintenance guidelines to help farmers keep their gearboxes in top condition. Timely maintenance not only prevents costly breakdowns but also ensures that the gearbox continues to operate smoothly, maintaining the accuracy of fertilizer application.

The integration of technology in fertilizer spreader gearboxes is an emerging trend that is poised to further enhance their capabilities. Advanced control systems, such as variable speed drives and automated calibration tools, are being incorporated into gearbox designs to provide even greater precision and adaptability. These technological advancements allow farmers to fine-tune their fertilizer application based on real-time data, such as soil nutrient levels and weather conditions, contributing to more informed and efficient farming practices.

In conclusion, fertilizer spreader gearboxes are an indispensable component of modern agricultural machinery, playing a crucial role in the efficient and sustainable distribution of fertilizers. Their design and functionality are tailored to meet the demanding requirements of agricultural environments, ensuring uniform and controlled fertilizer application. The durability, efficiency, and ease of maintenance of these gearboxes contribute to their reliability and effectiveness, while technological advancements promise to further enhance their performance. As the agricultural sector continues to evolve, the importance of well-designed and well-maintained fertilizer spreader gearboxes will only grow, underpinning the ongoing quest for higher crop yields and environmental stewardship. The fertilizer spreader gearbox, with its critical role in the agricultural process, stands as a testament to the ingenuity and innovation that drive the industry forward.

English

English 中文简体

中文简体 Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)