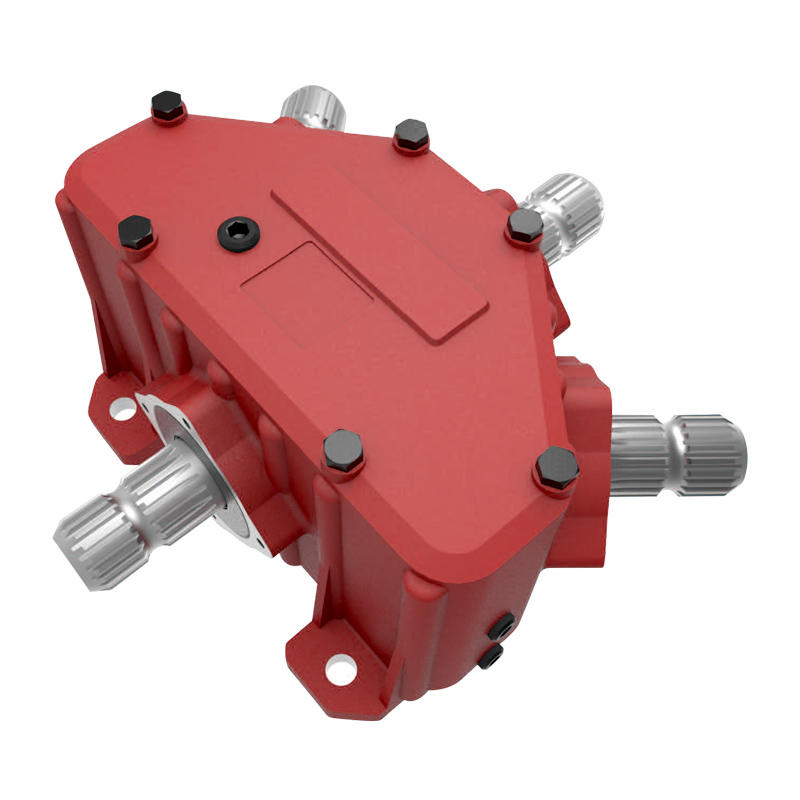

Sale High Quality Mixer Machine Gearbox Manufacturer Maker

In the realm of industrial processes, the mixer gearbox stands out as a pivotal component in various applications, ranging from food processing to chemical manufacturing. These gearboxes play a crucial role in ensuring good performance and efficiency of mixer machines, thereby significantly impacting production processes.

Mixer gearboxes are engineered to withstand heavy loads and continuous operation, thus enhancing the durability of mixer machines. One of the primary advantages of mixer gearboxes is their ability to provide precise speed control. By efficiently transmitting power from the motor to the mixing components, these gearboxes enable operators to adjust rotational speeds according to specific process requirements, ensuring mixing results.

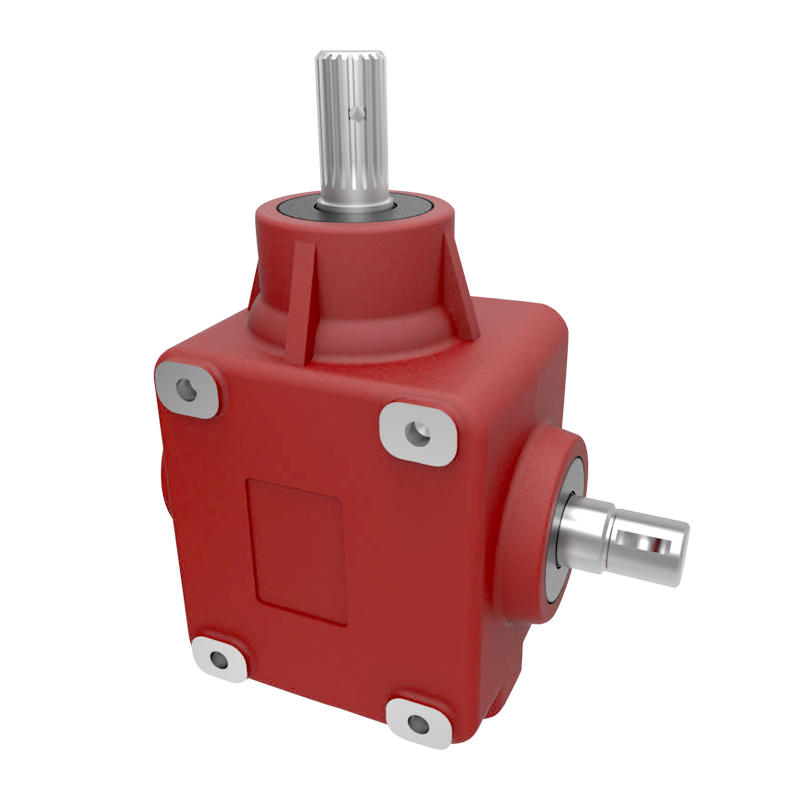

Mixer gearboxes facilitate efficient power transmission and reduce energy losses during operation. Whether it's blending ingredients in the food industry or homogenizing chemicals in pharmaceuticals, mixer gearboxes offer versatility in various applications. Their adaptable design allows for customization to meet specific mixing requirements, making them assets across diverse industrial sectors.

Despite their robustness, mixer gearboxes feature a compact design that optimizes space utilization within production facilities. With precision-engineered components and advanced lubrication systems, mixer gearboxes ensure smooth and consistent operation and reduce vibrations and noise levels. By mitigating stress on mixer components and reducing wear and tear, mixer gearboxes extend the longevity of mixer machines. This prolonged lifespan translates to increased return on investment for industrial operators, as they can rely on their equipment for years to come.

Manufacturers offer a range of customization options for mixer gearboxes, allowing users to tailor these components to their specific application requirements. Mixer gearboxes are designed for ease of maintenance, with accessible inspection points and replaceable components.

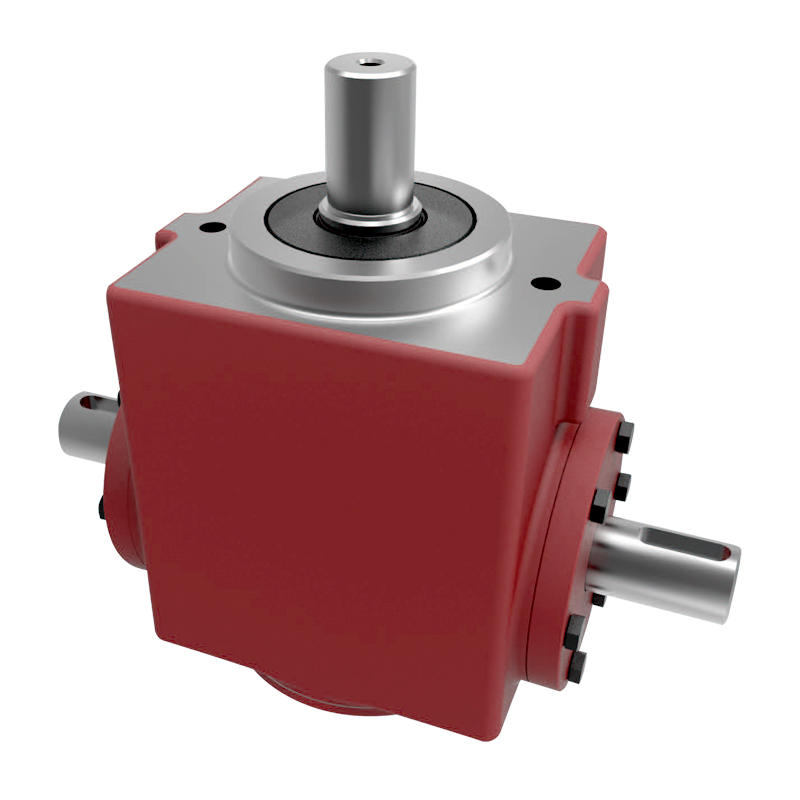

Mixer machines play a vital role in various industries, ranging from food processing to chemical manufacturing. A mixer machine gearbox serves as the powerhouse, enabling the machine to blend, mix, and homogenize materials effectively.

Mixer machine gearboxes are engineered to deliver performance by efficiently transferring power from the motor to the mechanism. One of the key advantages of mixer machine gearboxes is their ability to provide variable speed control. This feature allows operators to adjust the mixing speed according to specific requirements, whether it's gentle blending or high-speed agitation. Such flexibility enhances process control and product quality.

Mixer machine gearboxes are designed to transmit high torque without compromising on efficiency. Modern mixer machine gearboxes are compactly designed, occupying minimal space within the machine assembly. Mixer machine gearboxes are constructed using high-quality materials and precision engineering to withstand the rigors of continuous operation.

Efficient power transmission mechanisms employed in mixer machine gearboxes help reduce energy losses during operation. Mixer machine gearboxes are designed for ease of maintenance, with accessible components and simplified servicing procedures. This reduces downtime for maintenance tasks, allowing for greater uptime and productivity in production environments.

Mixer machine gearboxes are compatible with a wide range of mixer machine configurations and applications. Whether it's a batch mixer, continuous mixer, or specialized mixer for specific industries, gearbox options are available to suit diverse requirements.

Mixer machine gearboxes play a pivotal role in optimizing the performance, reliability, and efficiency of mixer machines across various industries. Their ability to provide variable speed control, transmit high torque, and deliver consistent results makes them components in modern manufacturing processes. By investing in high-quality mixer machine gearboxes, businesses can enhance productivity, reduce downtime, and maintain a competitive edge in today's dynamic market landscape.

English

English 中文简体

中文简体 Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)