Home / News / Industry News / Designing for Efficiency: The Role of Agricultural Manure Spreader Gearbox Suppliers

OEM agricultural manure spreader gearbox supplier, agricultural manure spreader gearbox supplier Maker

As a designer in the agricultural machinery sector, my focus is on creating tools that not only enhance farming productivity but also ensure the sustainability and health of the land. One of the key components in the design of agricultural manure spreaders is the gearbox. This article delves into the importance of selecting the right agricultural manure spreader gearbox supplier, the considerations in the design process, and the impact of a well-functioning gearbox on the overall performance of the spreader.

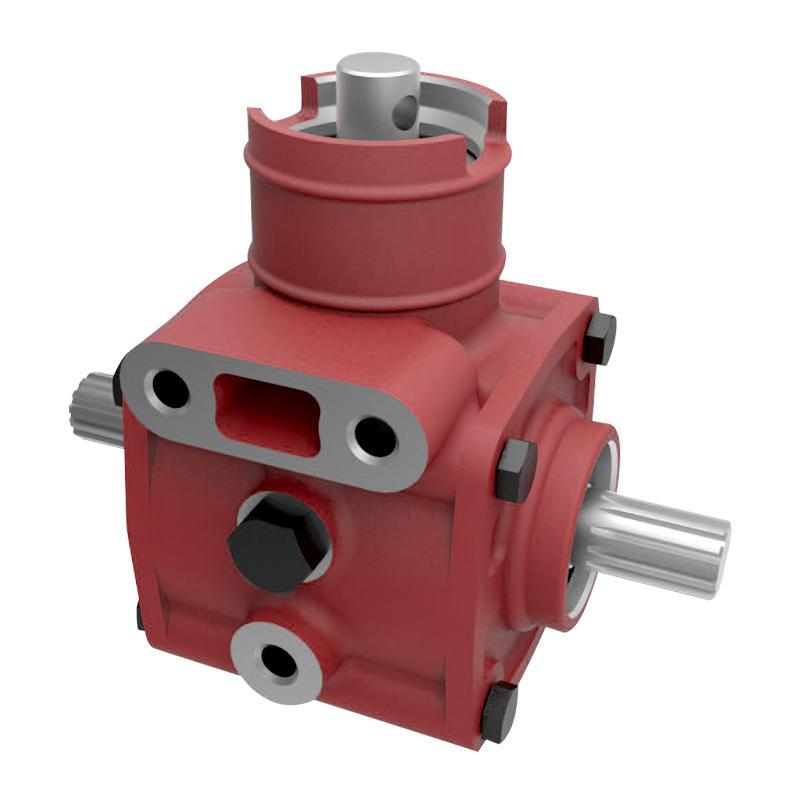

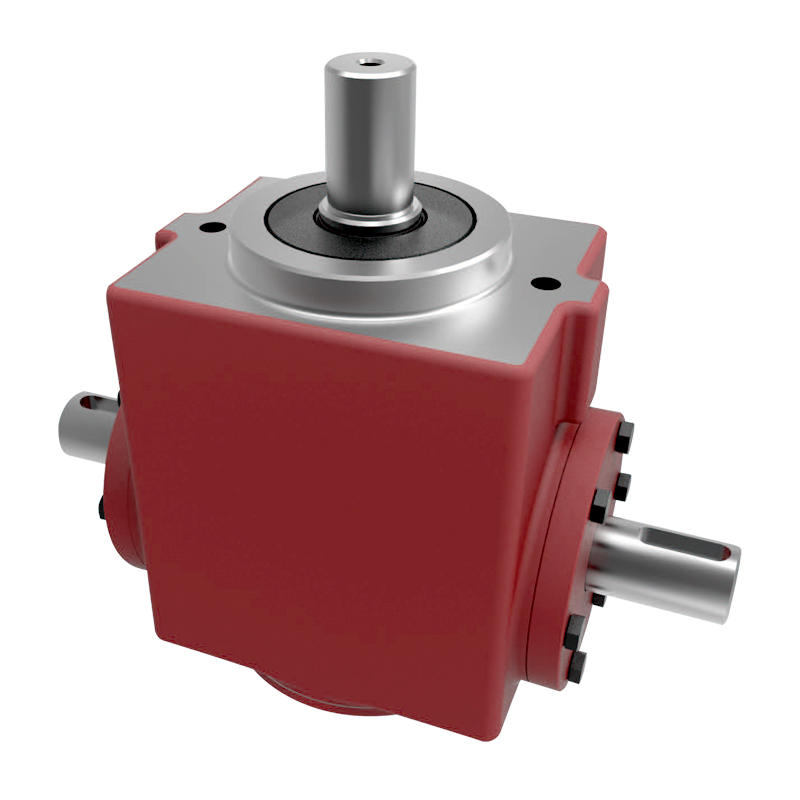

The precision gearboxes is the driving force behind the even distribution of manure across fields. It is responsible for the mechanical operation that ensures a consistent spread pattern, which is crucial for maintaining soil fertility and crop health. As a designer, I understand the need for a gearbox that is not only durable but also capable of handling the varying conditions of farmland.

The selection of an agricultural manure spreader gearbox supplier is a critical decision in the design process. Suppliers must have a proven track record of producing gearboxes that are robust, reliable, and designed specifically for agricultural use. They should also offer a range of gearboxes to accommodate different spreader sizes and operational requirements.

When designing the gearbox for an agricultural manure spreader, material selection is paramount. The gearbox must be made from materials that can withstand the corrosive nature of manure and the elements. Stainless steel and other corrosion-resistant alloys are often the materials of choice, as they provide the necessary durability and longevity.

The design of the gearbox must also consider the torque requirements of the spreader. Different types of manure, such as liquid or solid, will exert different levels of resistance on the gearbox. The gearbox must be capable of handling these varying loads without overheating or breaking down. This requires a careful balance of gear ratios and component strength.

Innovation plays a significant role in the design of agricultural manure spreader gearboxes. As a designer, I am constantly exploring new technologies and materials that can improve the efficiency and reliability of these gearboxes. This includes the use of advanced lubricants, wear-resistant coatings, and electronic control systems that can monitor and adjust the gearbox's performance in real-time.

The supplier's ability to customize gearboxes to meet specific design requirements is another important factor. As a designer, I value suppliers who are willing to collaborate and adapt their products to fit the unique needs of each agricultural manure spreader project. This collaboration ensures that the final product is tailored to the specific application, maximizing its effectiveness and longevity.

Maintenance and service are also considerations when choosing an agricultural manure spreader gearbox supplier. The supplier should provide comprehensive support, including easy access to replacement parts, detailed maintenance guides, and responsive customer service. This ensures that any issues with the gearbox can be quickly resolved, minimizing downtime and maintaining the spreader's operational efficiency.

In conclusion, the role of an agricultural manure spreader gearbox supplier is integral to the success of any farming operation. As a designer, I prioritize suppliers who offer high-quality, durable, and customizable gearboxes that can withstand the demands of agricultural use. A well-designed and well-maintained gearbox is the backbone of an effective manure spreader, ensuring that nutrients are evenly distributed across the land, promoting healthy crop growth, and supporting sustainable farming practices. The right gearbox supplier is a partner in this mission, contributing to the overall efficiency and productivity of the agricultural machinery.

English

English 中文简体

中文简体 Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)