Home / News / Industry News / Demystifying Post Hole Digger Gearboxes: A Customer's Comprehensive Exploration

Sales Post Hole Digger Gearboxes, Post Hole Digger Gearboxes Exporter, Post Hole Digger Gearboxes Factory

In the realm of landscaping and fencing, where the precision of every post placement matters, the Post Hole Digger Gearbox emerges as a vital component, quietly powering the machinery that transforms your vision into reality. This article is crafted from the perspective of a customer, unraveling the intricacies of Post Hole Digger Gearboxes to empower you with the knowledge needed to make informed decisions. Whether you're a seasoned DIY enthusiast or a first-time homeowner venturing into the world of post hole digging, this guide aims to demystify the gearbox, making it a tangible and approachable aspect of your outdoor projects.

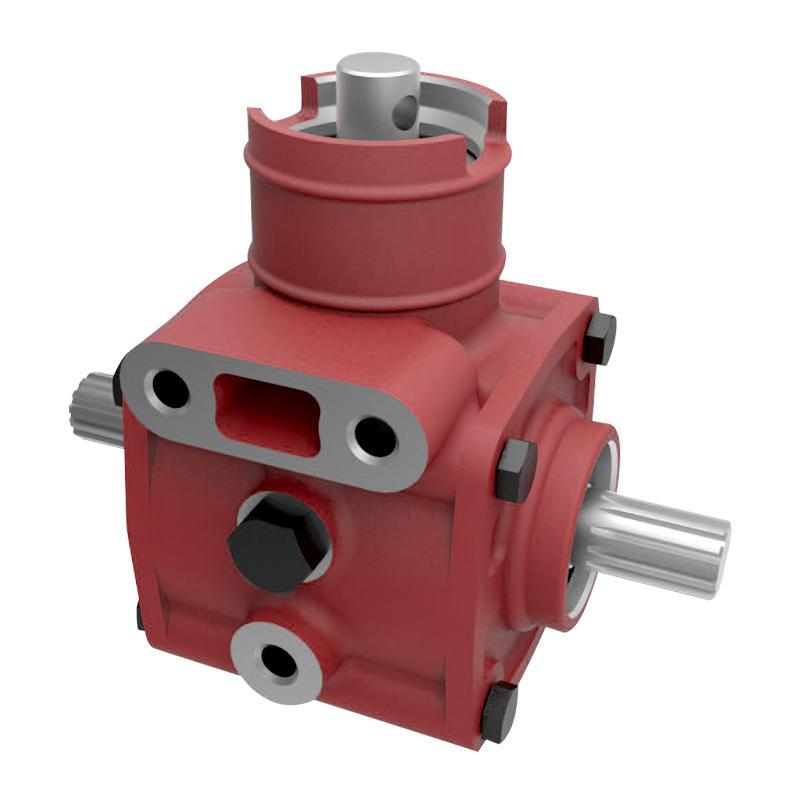

Introduction to Post Hole Digger Gearboxes: Post Hole Digger Gearboxes serve as the mechanical heart of post hole digging equipment, channeling power from the engine to the auger with precision and efficiency. As a customer, understanding the role of the gearbox in your post hole digger is akin to unlocking the engine's secret language – you may not see it, but its influence is undeniable.

The Silent Workhorse: Post Hole Digger Gearbox Basics: At its core, a Post Hole Digger Gearbox is a marvel of mechanical engineering, orchestrating the movement of augers and the application of torque to break through the earth. This fundamental understanding is the gateway to appreciating the importance of a reliable gearbox in ensuring efficient digging and minimizing strain on the operator.

Types of Post Hole Digger Gearboxes: Tailoring to Your Needs: Just as the needs of every landscaping project differ, so do the types of Post Hole Digger Gearboxes available. Understanding the variations, from standard gear drives to planetary gear systems, enables customers to align their choice with the specific demands of their digging tasks. Each type comes with its unique set of advantages and considerations.

Auger Size and Gear Ratio Dynamics: The Dance of Precision: The relationship between auger size and gear ratio is a crucial dynamic that influences the efficiency and precision of post hole digging. Customers benefit from grasping the nuances of this dance – where the choice of auger size and the corresponding gear ratio impact the depth and diameter of the holes being dug. This knowledge ensures that the equipment aligns with the project requirements.

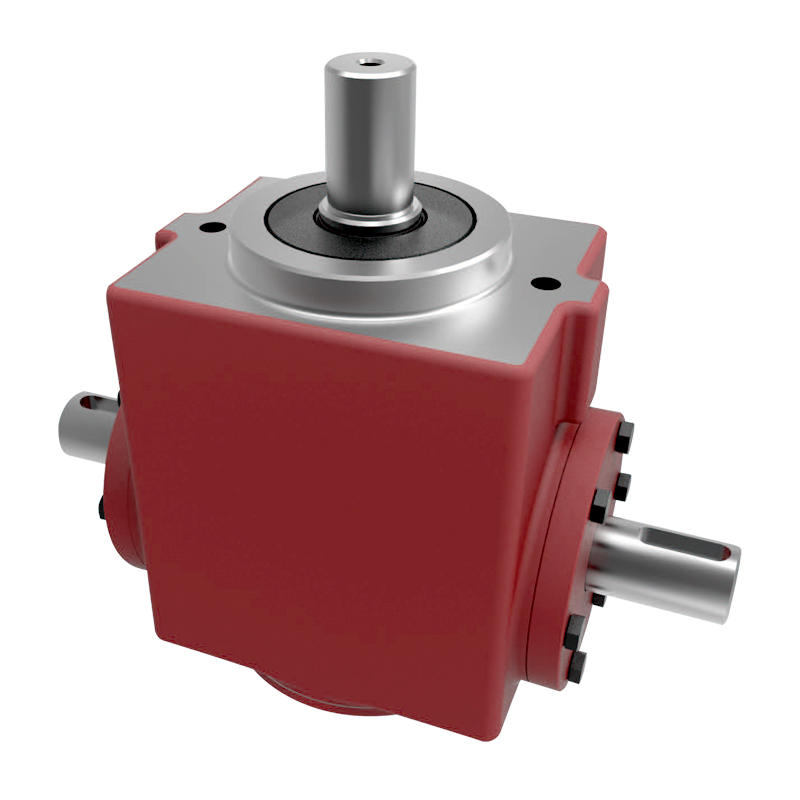

Material Matters: Durability and Reliability: Post Hole Digger Gearboxes are subjected to substantial stress during operation, making the choice of materials a pivotal consideration for customers. From cast iron to aluminum alloys, the materials used in gearbox construction impact not only durability but also overall weight and maintenance requirements. Understanding these material dynamics aids customers in selecting gearboxes that withstand the rigors of outdoor use.

Lubrication Systems: Preserving Efficiency and Longevity: The longevity and efficiency of a Post Hole Digger Gearbox hinge on proper lubrication. Customers often encounter a choice between oil bath and grease lubrication systems. Each has its merits, and understanding the implications of this choice helps customers make decisions aligned with their maintenance preferences and schedules.

Seals and Bearings: Guardians of Operational Integrity: Seals and bearings may not be the stars of the show, but they play a crucial role in preserving the operational integrity of a Post Hole Digger Gearbox. These components protect the gearbox from external elements, ensuring smooth operation and prolonging its life. A customer who appreciates the importance of these details contributes significantly to the longevity of their equipment.

Power Transmission: Understanding the Mechanism: For customers, delving into the intricacies of power transmission mechanisms in Post Hole Digger Gearboxes unveils the magic behind the digging process. The interplay between gears and shafts is a dance of precision, ensuring that the power generated by the engine is efficiently channeled to the auger. Understanding this mechanism empowers customers to troubleshoot and appreciate the nuances of gearbox operation.

Noise Levels: A Consideration for Operator Comfort: The noise generated during post hole digging can impact not only the efficiency of the operation but also the comfort of the operator. Customers seeking a more pleasant digging experience should pay attention to gearbox designs that prioritize noise reduction through innovative engineering. A quieter gearbox contributes to a more enjoyable and less fatiguing digging process.

Installation and Compatibility: Ensuring a Seamless Fit: Customers often face challenges related to compatibility when replacing or upgrading a Post Hole Digger Gearbox. Understanding the installation process, including bolt patterns and shaft sizes, is crucial to ensuring a seamless fit. Manufacturers provide specifications, and customers benefit from cross-referencing these details with their specific digger model.

Maintenance Guidelines: Maximizing Longevity: While Post Hole Digger Gearboxes are designed to endure tough conditions, regular maintenance is key to maximizing their lifespan. Customers who invest time in simple upkeep tasks, such as checking lubricant levels and inspecting seals, contribute significantly to the overall health of their digging equipment.

Brand Reputation: A Customer's North Star: In a market brimming with options, the reputation of the brand serves as a guiding star for customers. Established brands with a history of manufacturing reliable and durable Post Hole Digger Gearboxes instill confidence. Customer reviews and testimonials also provide valuable insights, helping customers make informed decisions based on real-world experiences.

Common Issues and Troubleshooting: Empowering Customers: No piece of machinery is immune to issues, and Post Hole Digger Gearboxes are no exception. Customers benefit from familiarizing themselves with common problems such as leaks or loss of power transmission. Knowing the troubleshooting steps allows customers to address minor issues promptly and seek professional assistance when needed.

Evaluating Your Digging Needs: A Customer-Centric Approach: The key to selecting the right Post Hole Digger Gearbox lies in evaluating the specific needs of your digging projects. Factors such as soil type, hole diameter, and the frequency of use all influence the gearbox requirements. A customer-centric approach involves aligning the features and specifications of the gearbox with the unique characteristics of your digging tasks.

Conclusion: Empowered Decision-Making for Efficient Digging: As a customer embarking on the world of Post Hole Digger Gearboxes, the journey is not just about acquiring a mechanical component but about investing in the efficiency and success of your outdoor projects. Armed with knowledge about gearbox types, materials, lubrication systems, and maintenance practices, you embark on a journey of empowered decision-making. The unsung hero behind your digging endeavors, the Post Hole Digger Gearbox, becomes not just a piece of machinery but a crucial ally in your quest for precise and efficient post hole digging.

English

English 中文简体

中文简体 Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)