Selecting the appropriate gearbox for your machinery is a pivotal decision that can significantly impact performance, efficiency, and overall functionality. Two commonly considered options are the Machinery Gearbox and the Box Gearbox. Today, we will explore the key differences and considerations when choosing between these two gearbox types.

Machinery Gearbox:

1. Versatility:

The Machinery Gearbox is known for its versatility. It can be adapted to a wide range of machinery and equipment types, making it a popular choice in various industries, including manufacturing, construction, and agriculture.

2. Power Transmission:

Machinery Gearboxes are designed to efficiently transmit power from a motor or engine to various components within a machine. This includes translating rotational speed and torque to suit the specific requirements of the equipment.

3. Speed Control:

Machinery Gearboxes often provide variable speed control, allowing operators to adjust the machinery's speed to meet different operational demands. This flexibility is essential in applications where precise control is needed.

4. Torque Amplification:

These gearboxes excel at torque amplification. They can increase the torque output while decreasing the rotational speed, which is crucial for heavy machinery that needs sufficient force for tasks like lifting and moving heavy loads.

5. Customization:

Machinery Gearboxes can be customized to suit the specific needs of a machine. Engineers can choose gear ratios, input and output shaft designs, and housing configurations to optimize performance.

6. Durability:

Due to their wide range of applications, Machinery Gearboxes are typically built to be durable and reliable. They can withstand the demands of heavy-duty machinery and extended operational hours.

7. Maintenance:

Maintenance of Machinery Gearboxes is essential to ensure continued efficiency. However, they are often designed with easy access to lubrication points and wear components, simplifying upkeep.

8. Applications:

Machinery Gearboxes find applications in various equipment types, including conveyor systems, industrial robots, machine tools, and more. They are versatile enough to accommodate the needs of different industries.

9. Complexity:

Depending on the application, Machinery Gearboxes can be relatively complex, involving multiple gears and components. This complexity can offer precise control but may require more maintenance and can be costlier to manufacture.

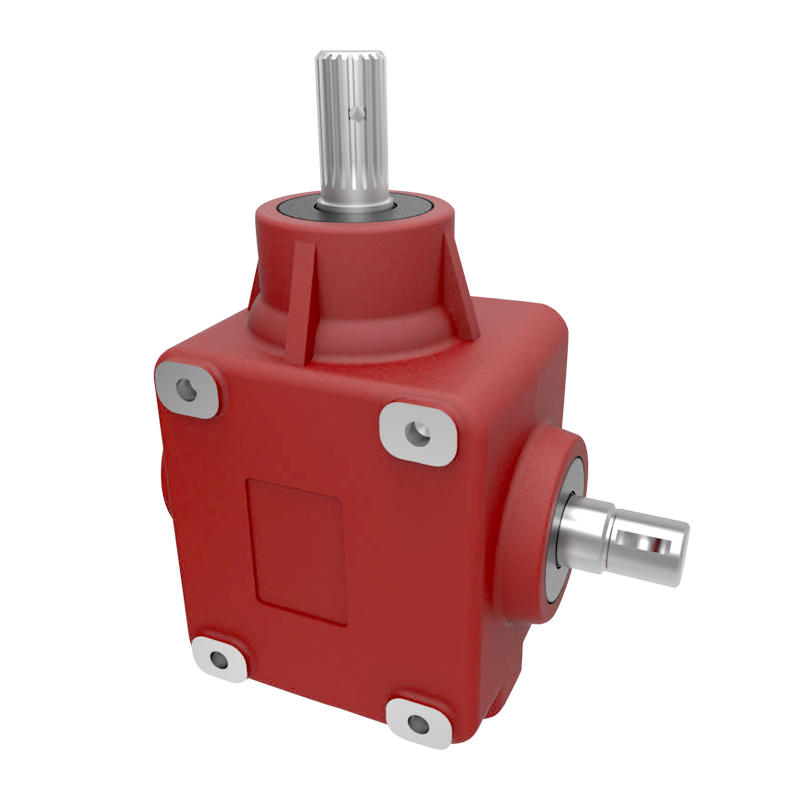

Box Gearbox:

1. Simplicity:

Box Gearboxes are known for their simplicity. They are typically compact and straightforward in design, making them easy to install and maintain. This simplicity is particularly advantageous in applications where a basic gearbox design suffices.

2. Fixed Gear Ratio:

Unlike Machinery Gearboxes, Box Gearboxes often have a fixed gear ratio. This means they may not offer the same degree of speed and torque adjustment as their counterparts. However, this fixed ratio can be suitable for specific applications.

3. Robustness:

Box Gearboxes are robust and sturdy. They are commonly used in equipment like agricultural machinery, where durability and reliability are essential due to harsh outdoor conditions.

4. Cost-Effectiveness:

Box Gearboxes are often more cost-effective to manufacture and maintain than Machinery Gearboxes. Their simplicity translates into lower production costs and reduced maintenance requirements.

5. Limited Applications:

While Box Gearboxes are highly suitable for certain applications, their lack of versatility may limit their use in more complex machinery or in industries requiring variable speed control.

6. Ease of Installation:

Box Gearboxes are typically easier to install due to their compact and straightforward design. This can save both time and labor costs during equipment assembly.

7. Applications:

Common applications of Box Gearboxes include agricultural machinery, small construction equipment, and simple conveyor systems. They are particularly well-suited for tasks where a basic, reliable gearbox is sufficient.

8. Maintenance:

Maintenance of Box Gearboxes is relatively straightforward, often involving routine lubrication and occasional inspections. Their robust design contributes to a longer service life with minimal upkeep.

The choice between a Machinery Gearbox and a Box Gearbox depends on the specific needs of your machinery and the nature of your operations. Both gearbox types have their strengths and weaknesses, and making an informed decision is crucial to optimizing performance and efficiency in your equipment.

English

English 中文简体

中文简体 Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)