Home / News / Industry News / A Designer's Insight into Rotary Tiller Gearboxes in Modern Agriculture

Wholesale rotary tiller gearboxes, rotary tiller gearboxes Company, rotary tiller gearboxes For Sale

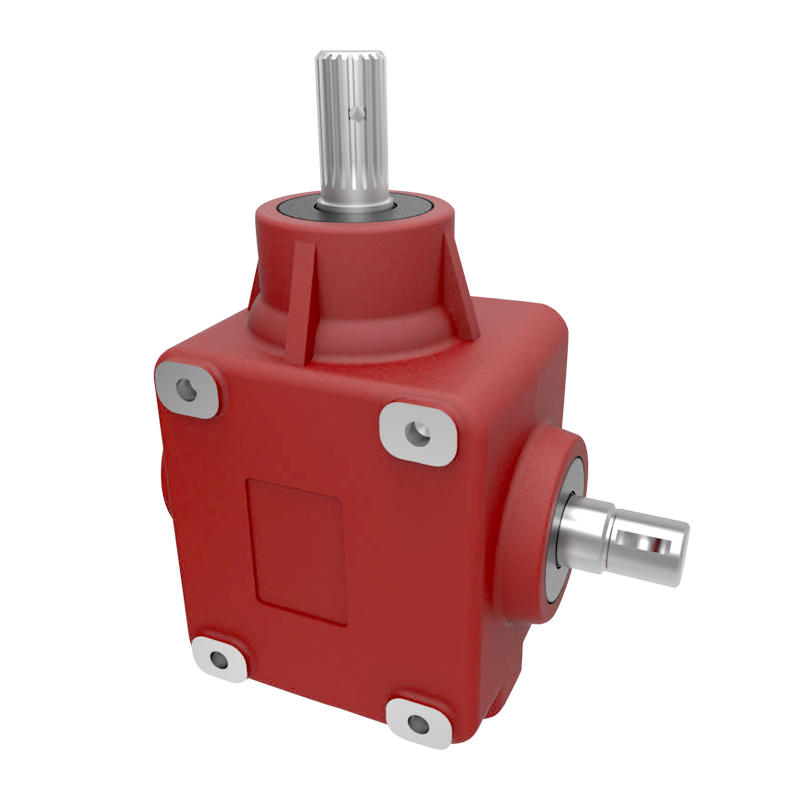

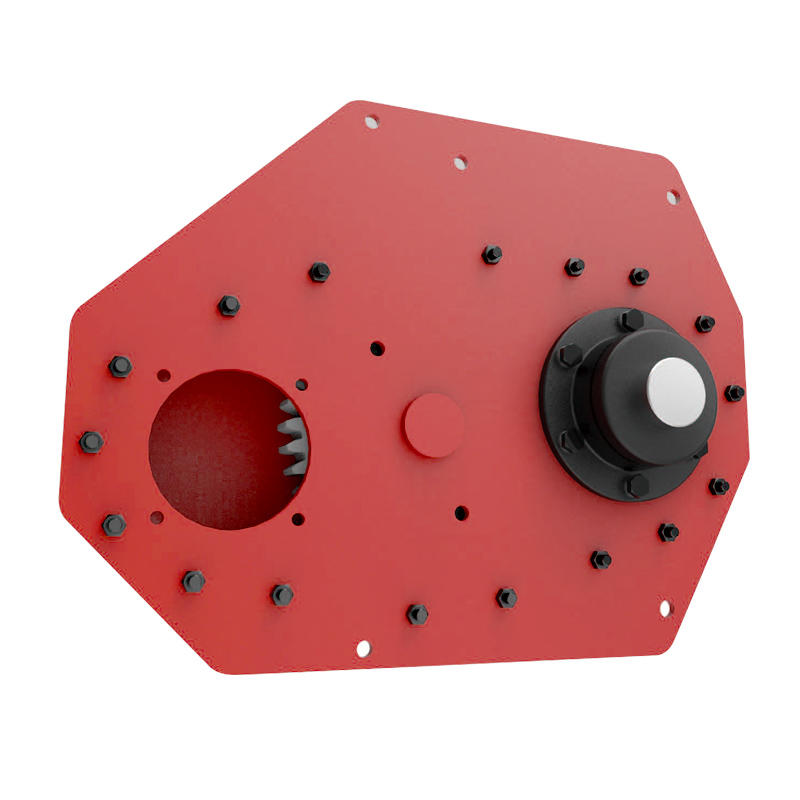

In the realm of agricultural machinery, the rotary tiller gearbox stands as a crucial component, embodying the marriage of functionality and efficiency. As designers, our role is to navigate the intricate landscape of rotary tiller gearboxes, creating solutions that meet the demanding needs of modern farming without compromising on durability and adaptability. This article delves into the significance, design intricacies, applications, and the pivotal role that rotary tiller gearboxes play in shaping the efficiency of agricultural practices.

The Significance of Rotary Tiller Gearboxes in Agriculture

Cultivating Soil with Precision

Rotary tiller gearboxes play a pivotal role in the process of soil cultivation. Their primary function is to transmit power from the tractor to the rotary tiller blades, ensuring that the soil is broken up, aerated, and prepared for planting with precision. The gearbox's ability to adapt to varying soil conditions makes it an indispensable tool for farmers.

Versatility in Farming Practices

The versatility of rotary tiller gearboxes lies in their adaptability to different types of tractors and soil conditions. Designers focus on creating gearboxes that can efficiently transmit power while providing farmers with the flexibility to adjust the depth and speed of the tiller blades. This adaptability enhances the versatility of rotary tillers across diverse farming practices.

Design Considerations for Rotary Tiller Gearboxes

Robust Construction for Field Durability

The demanding nature of agricultural work requires rotary tiller gearboxes to be constructed with robust materials. Designers prioritize durability by selecting materials that can withstand the rigors of field operations, including exposure to rocks, roots, and varying soil types.

Customizable Gear Ratios for Efficiency

Efficiency is a key consideration in designing rotary tiller gearboxes. Designers focus on customizable gear ratios to ensure that the gearbox can efficiently transmit power from the tractor to the tiller blades, adapting to different tractor speeds and soil conditions. This customization contributes to fuel efficiency and optimal performance.

Sealed Housing for Contaminant Protection

Agricultural environments expose rotary tiller gearboxes to dust, debris, and moisture. Designers incorporate sealed housing designs to protect internal components from contaminants, ensuring the longevity of the gearbox. Effective sealing prevents premature wear and minimizes the need for frequent maintenance.

Efficient Lubrication Systems for Smooth Operation

Smooth operation is essential for rotary tiller gearboxes to effectively till the soil. Designers integrate efficient lubrication systems that ensure proper lubrication of gears and bearings. This contributes to smooth gearbox operation, minimizes friction, and extends the overall lifespan of the gearbox.

Applications of Rotary Tiller Gearboxes in Agriculture

Seedbed Preparation: Creating an Ideal Planting Environment

Rotary tiller gearboxes are instrumental in seedbed preparation, where the soil is tilled to create an ideal environment for planting. The gearbox allows farmers to adjust the tiller depth and speed, ensuring that the soil is adequately prepared for optimal seed germination.

Weed Control: Tackling Unwanted Growth

The adaptability of rotary tiller gearboxes makes them effective tools for weed control. By breaking up and turning over the soil, the gearbox helps to disrupt weed growth, providing farmers with a natural and efficient method for weed management.

Residue Incorporation: Enhancing Soil Fertility

After harvesting, crop residues often remain on the field. Rotary tiller gearboxes aid in residue incorporation by efficiently incorporating crop residues into the soil. This process contributes to improved soil fertility and prepares the field for the next planting season.

Stubble Management: Addressing Crop Residue

Efficient stubble management is essential in modern agriculture. Rotary tiller gearboxes assist in breaking down and incorporating crop residues into the soil, preventing the accumulation of stubble. This not only promotes better soil health but also facilitates the planting of subsequent crops.

Challenges and Solutions in Designing Rotary Tiller Gearboxes

Addressing Varying Soil Conditions

One of the challenges in designing rotary tiller gearboxes is addressing the varying soil conditions encountered in agriculture. Designers employ adaptable designs and customizable features to ensure that the gearbox can efficiently operate in different soil types, from sandy to clayey soils.

Balancing Power Transmission with Fuel Efficiency

Achieving an optimal balance between power transmission and fuel efficiency is a key consideration. Designers focus on customizable gear ratios and efficient designs to ensure that rotary tiller gearboxes transmit sufficient power for effective tillage while maximizing fuel efficiency.

Managing Heat Generation during Operation

Continuous operation in the field can lead to heat generation within the gearbox. Designers incorporate cooling features and efficient lubrication systems to manage heat effectively, preventing overheating and ensuring the gearbox operates within safe temperature limits.

Maintaining Rotary Tiller Gearboxes for Longevity

Regular Inspections for Wear and Tear

Routine inspections are crucial to identify signs of wear and tear in rotary tiller gearboxes. Designers and maintenance professionals should conduct regular checks on gears, bearings, and seals. Timely identification of issues allows for proactive maintenance.

Lubrication Management

Efficient lubrication is paramount for the longevity of rotary tiller gearboxes. Regular checks on lubrication levels and the condition of lubricants help prevent premature wear. Designers often provide clear guidelines on lubrication intervals and suitable lubricants for different operating conditions.

Alignment Checks for Smooth Operation

Proper alignment is essential for smooth gearbox operation. Misalignment can lead to increased wear and reduced efficiency. Regular alignment checks, especially after maintenance or repairs, contribute to the overall performance and longevity of the gearbox.

Conclusion: Designing the Future of Efficient Tillage

In conclusion, rotary tiller gearboxes emerge as silent champions in modern agriculture, shaping the efficiency and productivity of tillage practices. As designers, our role is to navigate the unique challenges of designing gearboxes that can withstand the demanding conditions of the field while providing farmers with efficient and adaptable tools. The significance of rotary tiller gearboxes in seedbed preparation, weed control, residue incorporation, and stubble management underscores their importance in modern farming. By addressing design considerations, challenges, and maintenance practices, we contribute to the longevity and effectiveness of rotary tiller gearboxes, ensuring that they remain integral to the future of efficient tillage in agriculture.

English

English 中文简体

中文简体 Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)