A Reducer, a Gearbox, and a Geared Motor are mechanical devices that play distinct roles in power transmission, speed control, and torque management. While they share similarities, they also have crucial differences in design, functionality, and applications.

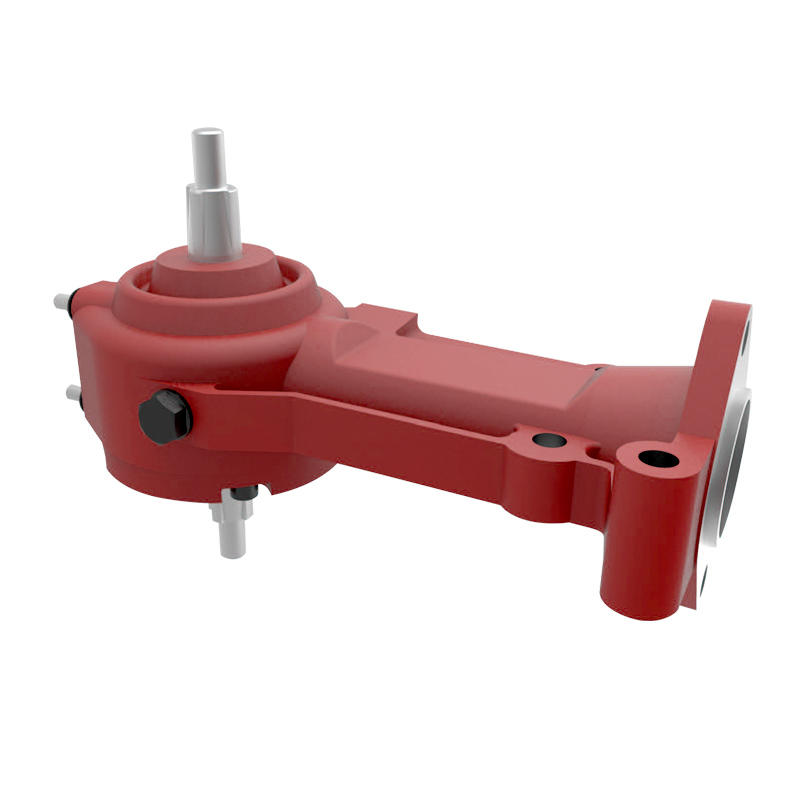

Reducer:

A Reducer, often referred to as a speed reducer or gear reducer, is a mechanical device primarily designed to reduce the speed of an input shaft while increasing the torque output. Its key characteristics include:

1. Design: Reducers typically consist of a set of gears arranged in various configurations, such as worm gears, helical gears, or planetary gears. These gears work together to reduce the speed of rotation.

2. Functionality: The primary function of a Reducer is speed reduction. It is used to slow down the rotational speed of an input shaft or motor while amplifying the torque output. This is essential for applications where high torque is needed to move heavy loads.

3. Applications: Reducers find extensive use in industries where precise control over speed and torque is crucial. Common applications include conveyor systems, winches, elevators, and machinery used in manufacturing, construction, and mining.

4. Advantages: Reducers are known for their ability to provide high torque, making them suitable for applications requiring the handling of heavy loads or where precise control of rotational speed is essential.

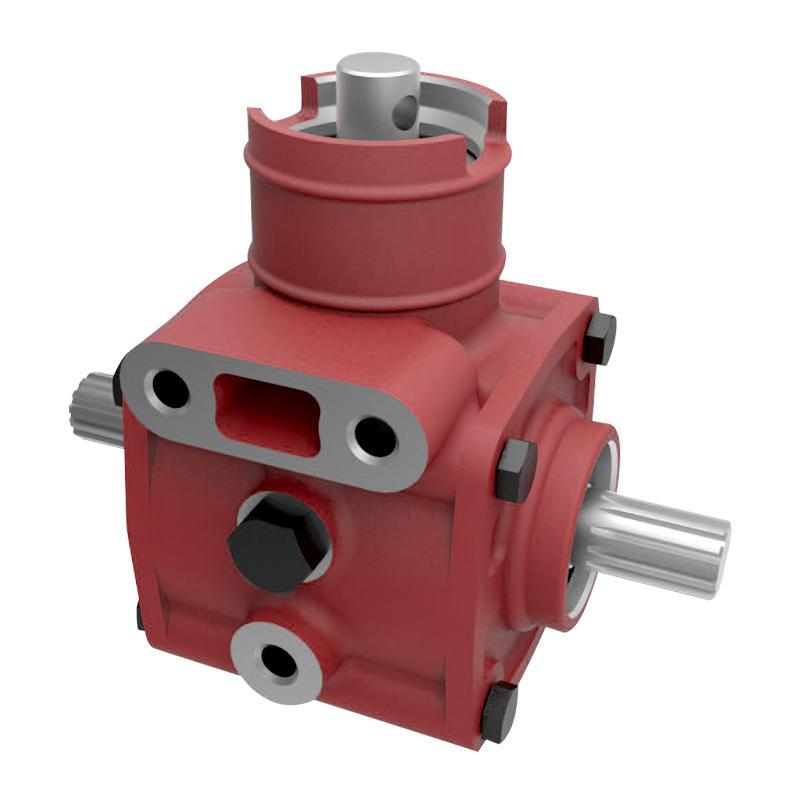

Gearbox:

A Gearbox is a versatile mechanical device designed to control the speed, torque, and direction of rotational motion. It encompasses a broader range of functions and applications:

1. Design: Gearboxes consist of multiple gears in various arrangements, including spur, helical, bevel, and planetary gears. The configuration of gears allows for diverse functionality.

2. Functionality: Gearboxes offer a wide range of functionalities, including speed reduction, speed increase (overdrive), torque amplification, and directional control (reversing the direction of rotation).

3. Applications: Gearboxes are used in diverse industries and applications, ranging from automotive transmissions to aerospace components, marine vessels, and industrial machinery. They provide precise control over rotational parameters.

4. Advantages: Gearboxes are adaptable to a multitude of tasks, offering versatility in controlling rotational motion. They are employed in scenarios where speed, torque, and direction need to be finely tuned.

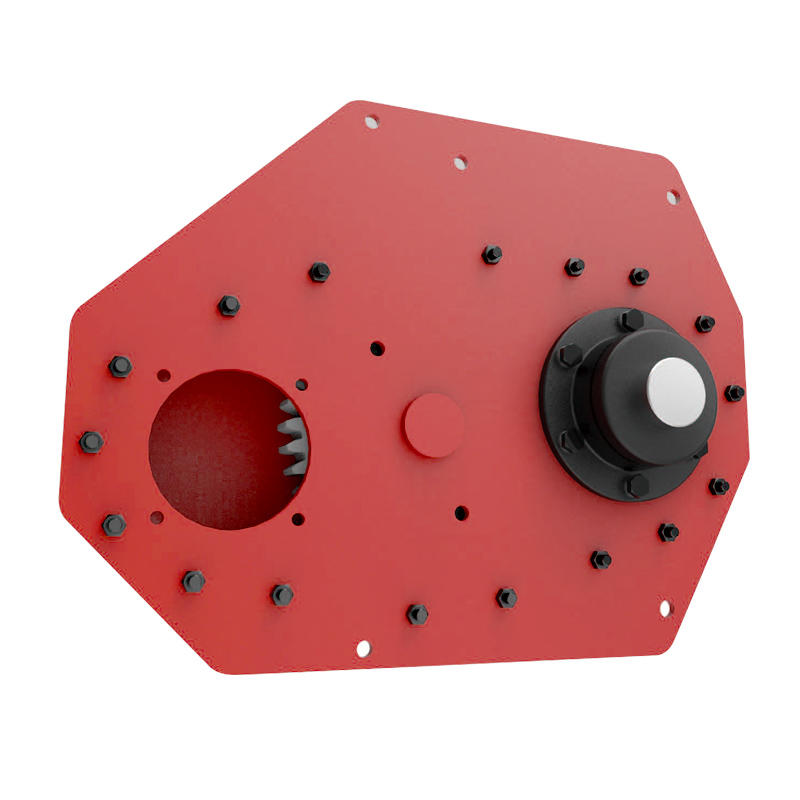

Geared Motor:

A Geared Motor is a combination of an electric motor and a gearbox integrated into a single unit. It merges the capabilities of both components:

1. Design: Geared Motors feature an electric motor directly connected to a gearbox, typically planetary or helical. This integration results in a compact and efficient power transmission unit.

2. Functionality: Geared Motors combine the capabilities of the motor (generating mechanical power) and the gearbox (speed reduction, torque amplification, and directional control). They are used for various applications requiring motion control.

3. Applications: Geared Motors are widely used in industries where a compact and efficient power transmission solution is needed. Common applications include conveyor systems, automated machinery, robotics, and appliances.

4. Advantages: Geared Motors simplify installation, reduce space requirements, and offer an efficient means of power transmission. They are ideal for applications demanding both motor-driven power and precise motion control.

While Reducers primarily focus on speed reduction and torque amplification, Gearboxes offer a broader range of functions and are adaptable to various applications. Geared Motors integrate the capabilities of both an electric motor and a gearbox, providing a compact and efficient solution for motion control. The choice between these components depends on the specific requirements of an application, including the need for speed control, torque, and space efficiency.

English

English 中文简体

中文简体 Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)