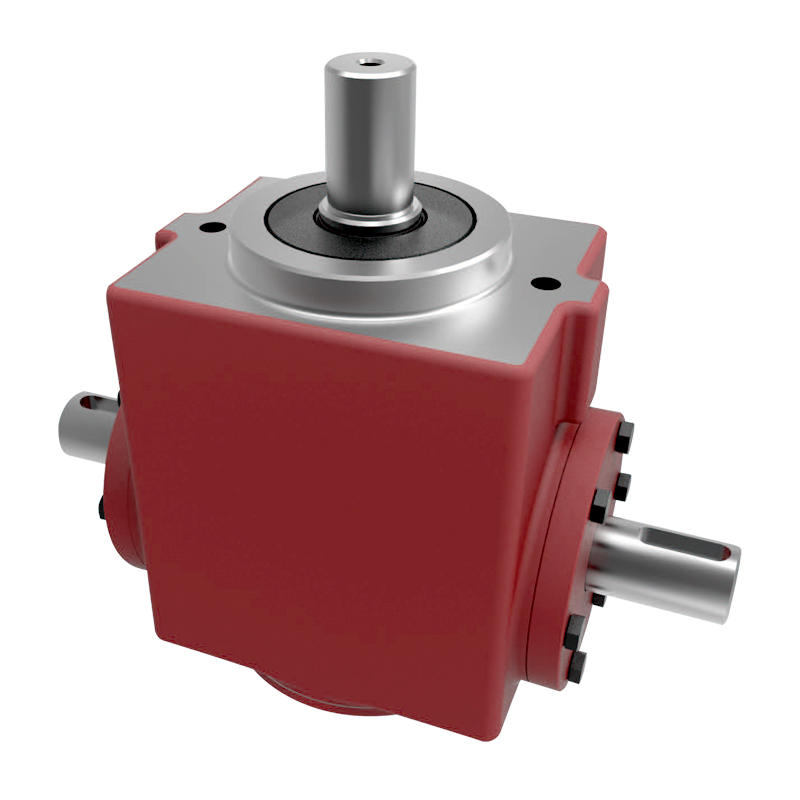

Tiller gearboxes are critical components in garden and agricultural equipment, designed to drive the tines or blades of rotary tillers. These gearboxes play a crucial role in breaking and preparing soil for planting. Understanding their key components and proper maintenance is essential to ensure their longevity and efficient performance.

Key Components of Tiller Gearboxes:

1. Input Shaft: The input shaft is connected to the power source, usually a tractor's power take-off (PTO) or an engine. It transfers rotational force to the gearbox.

2. Gears: Gears are at the heart of any gearbox. In tiller gearboxes, you'll typically find bevel gears, spur gears, and worm gears. These gears transmit power from the input shaft to the output shaft while providing the necessary speed reduction or increase.

3. Output Shaft: The output shaft extends from the gearbox and connects to the tiller's tines or blades. It transfers the rotational motion generated by the gears to the cutting or tilling mechanism.

4. Housing: The gearbox housing encases and protects the internal components from dirt, debris, and moisture. It also houses lubricating oil to ensure proper gear lubrication.

5. Bearings: Bearings support the rotating shafts and gears within the gearbox. They reduce friction, allowing for efficient power transmission and preventing premature wear of moving parts.

6. Seals: Seals prevent contaminants from entering the gearbox while retaining lubricating oil inside. They help maintain the gearbox's integrity and protect internal components from damage.

7. Lubrication System: A lubrication system ensures that all moving parts within the gearbox receive adequate lubrication. It typically consists of oil reservoirs, oil pumps, and distribution channels that deliver lubricating oil to critical areas.

8. Gear Shifting Mechanism (Optional): Some tiller gearboxes may include a gear shifting mechanism that allows operators to change the rotational speed of the tines or blades. This feature is useful when adapting to different soil conditions or tiller requirements.

9. Safety Mechanisms (Optional): In some models, safety features may be incorporated into the gearbox design. These can include overload protection systems to prevent damage to the gearbox or power source in case of excessive load or blockage.

Maintenance Considerations for Tiller Gearboxes:

1. Regular Inspection: Perform routine visual inspections of the gearbox for signs of oil leaks, damage, or loose components. Pay special attention to seals, bearings, and gear teeth.

2. Lubrication: Proper lubrication is crucial for gearbox longevity. Follow the manufacturer's recommendations for oil type and change intervals. Overfilling or underfilling with lubricating oil can lead to gearbox issues.

3. Seal Maintenance: Check seals for wear and damage. Replace damaged or deteriorated seals promptly to prevent contaminants from entering the gearbox.

4. Bearing Maintenance: Inspect bearings for wear, noise, or excessive play. Replace any worn or damaged bearings to prevent gearbox failure.

5. Gear Inspection: Examine gear teeth for signs of wear, chipping, or deformation. Damaged gears should be replaced immediately to ensure proper gear meshing and power transmission.

6. Tightening Fasteners: Periodically check and tighten fasteners, including bolts and screws, to ensure they are secure. Loose fasteners can lead to gearbox misalignment and potential damage.

7. Safety Checks: If your tiller gearbox includes safety mechanisms, such as overload protection, ensure they are functioning correctly. Regularly test these features to prevent equipment damage.

8. Gear Shifting Mechanism: If your gearbox has a gear shifting mechanism, follow the manufacturer's instructions for proper use and adjustment. Avoid shifting gears while the gearbox is under load to prevent damage.

9. Cleaning: Keep the gearbox and surrounding area clean of dirt, debris, and vegetation. Accumulated debris can lead to overheating and decreased gearbox efficiency.

The tiller gearboxes are vital components in soil preparation equipment, and their proper maintenance is essential to ensure efficient operation and longevity. Regular inspections, lubrication, seal and bearing maintenance, gear inspections, and adherence to safety and shifting mechanisms are crucial for keeping tiller gearboxes in excellent working condition.

English

English 中文简体

中文简体 Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)