Home / News / Industry News / Precision tools machining is a vital element of fertilizer spreader group gearboxes

Precision tools machining is a vital element of fertilizer spreader group gearboxes, contributing to the accuracy, performance, and reliability of power transmission inside these agricultural additives. Here are the characteristics related to precision gear machining in fertilizer spreader organization gearboxes:

Accurate Tooth Profiles: Precision equipment machining ensures that the tooth profiles of gears are correctly and constantly machined. This accuracy is important for maintaining a clean meshing motion between gears, reducing friction, and minimizing put on.

Tight Tolerances: The manufacturing technique includes adhering to tight tolerances, ensuring that the dimensions of each gear and associated additives meet unique layout specifications. This precision is crucial for attaining the intended equipment ratios and optimizing the gearbox's performance.

Smooth Surface Finishes: Gears go through precision machining to reap clean floor finishes. This reduces friction and wear, promoting green energy transmission and extending the lifespan of the gears.

Material Selection: Precision machining includes the usage of high-quality materials for equipment production. The desire of substances is critical for sturdiness, with commonplace options including hardened metallic or different alloys which can withstand the needs of agricultural programs.

Heat Treatment: Gears may undergo warmness remedy approaches as a part of precision machining. Heat remedy improves the hardness and strength of the gears, enhancing their resistance to wear and fatigue throughout continuous operation.

Profile Grinding: In some cases, precision gear machining involves profile grinding, a system that refines the form of the gear enamel with excessive accuracy. This guarantees superior engagement between gears, contributing to easy electricity transmission.

Consistent Pitch Diameter: Maintaining a consistent pitch diameter throughout gears is crucial for reaching the desired tools ratios. Precision machining guarantees that every tools inside the gearbox has the supposed pitch diameter, contributing to accurate velocity reduction and torque multiplication.

Reduced Backlash: Backlash, the play between meshing equipment enamel, can impact the precision of tools engagement. Precision machining minimizes backlash, ensuing in extra accurate and responsive equipment overall performance.

Balancing: Precision machining includes balancing approaches to make certain that gears are flippantly disbursed in phrases of weight. Balanced gears contribute to smoother operation, lowering vibrations and noise in the course of use.

Quality Control Measures: Throughout the precision machining procedure, rigorous exceptional manipulate measures are applied. This involves inspections and trying out to confirm that every equipment meets the specified requirements for dimensions, surface end, and basic performance.

Computer Numerical Control (CNC) Machining: CNC machining is frequently used in precision equipment manufacturing. This laptop-managed system allows for rather correct and repeatable machining, making sure consistency across more than one gear components.

Customization: Precision machining permits the customization of gear designs to healthy the precise requirements of fertilizer spreader group gearboxes. This can also consist of variations in tooth profiles, helix angles, or different parameters tailor-made to optimize overall performance.

Precision gear machining is vital for reaching the best stage of overall performance and reliability in fertilizer spreader organization gearboxes, ensuring that those agricultural components operate efficiently and supply accurate fertilizer distribution within the field.

.jpg?imageView2/2/format/jp2)

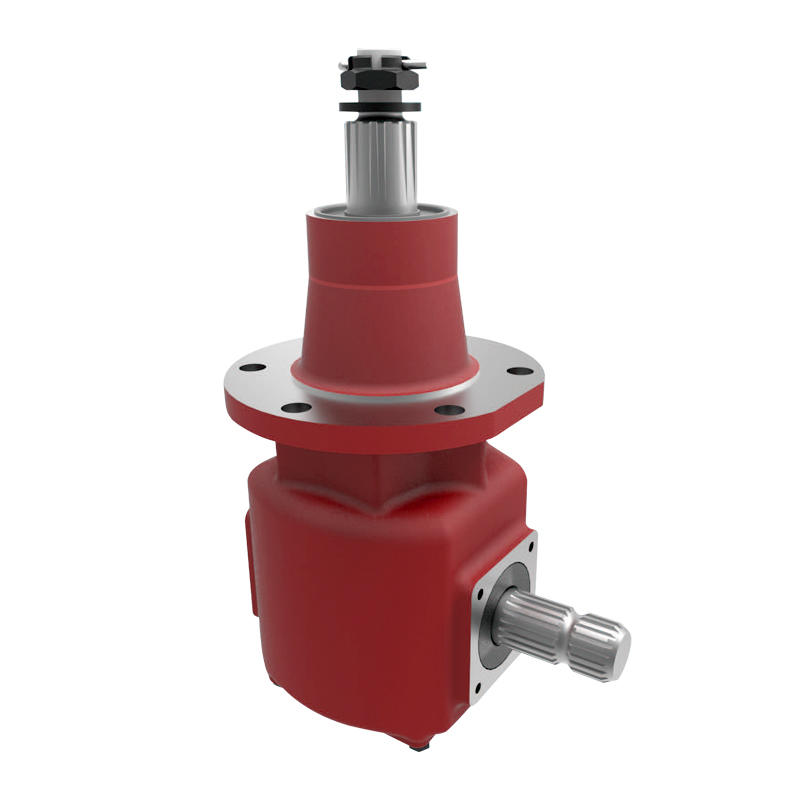

GEARBOX RM24

English

English 中文简体

中文简体 Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)