Home / News / Industry News / Precision engineering in put up hole digger gear reducers refers to the meticulous layout and production methods

Precision engineering in put up hole digger gear reducers refers to the meticulous layout and production methods that make sure the correct and reliable operation of the equipment gadget. Here are key characteristics related to precision engineering in publish hollow digger equipment reducers:

Accurate Gear Tooth Profiles: Precision engineering involves shaping the equipment enamel with excessive accuracy. Accurate teeth profiles are essential for clean meshing, reduced friction, and efficient power transmission. Computer-aided design (CAD) and production (CAM) technology are frequently employed to obtain precision in enamel profiles.

Tight Tolerances: Precision engineering continues tight tolerances all through the manufacturing method. This ensures that each element, together with gears and shafts, adheres carefully to certain dimensions. Tight tolerances make a contribution to the overall performance and reliability of the equipment system.

High-Quality Materials: Precision tools reducers are produced from excellent substances that provide durability, power, and resistance to wear. Common substances consist of hardened metallic or alloys, selected for his or her capability to resist the forces and stresses encountered in the course of digging in various soil situations.

Heat Treatment: Gears might also undergo warmth remedy tactics as a part of precision engineering. Heat remedy improves the hardness and strength of the gears, enhancing their resistance to wear, fatigue, and deformation at some point of prolonged use.

Profile Grinding: Precision engineering regularly involves profile grinding of equipment tooth. This process refines the shape and floor finish of the gear enamel with brilliant accuracy, contributing to easy operation and reducing wear.

Balancing: Precision equipment reducers are carefully balanced to make sure even distribution of weight. Balanced additives lessen vibrations throughout operation, selling smoother overall performance and minimizing stress at the gearbox and surrounding systems.

Computer Numerical Control (CNC) Machining: CNC machining is normally utilized in precision engineering. This laptop-controlled manner allows specific and repeatable manufacturing, ensuring consistency throughout a couple of components and contributing to the general precision of the equipment machine.

Sophisticated Design: Precision engineering involves state-of-the-art layout practices to optimize the geometry and arrangement of gears in the gearbox. This consists of issues for tooth profile, helix angle, and different parameters to attain the favored overall performance traits.

Smooth Surface Finishes: Gears and different vital additives go through precision machining to acquire smooth surface finishes. Smooth surfaces reduce friction, prevent unnecessary wear, and make contributions to green electricity transmission.

Alignment Accuracy: Accurate alignment of components is vital for precision engineering. Misalignment can lead to increased friction, noise, and wear. Precise alignment guarantees that gears mesh seamlessly, selling efficient energy transmission.

Quality Control Measures: Rigorous first-rate manipulate measures are applied during the producing system. This entails inspections and testing to verify that every equipment meets the specified requirements for dimensions, hardness, and universal overall performance.

Customization: Precision engineering lets in for personalization based totally at the specific necessities of submit hole digger equipment reducers. This can also consist of adjustments to gear ratios, tooth profiles, or different parameters to optimize performance for special soil conditions and digging programs.

By incorporating those characteristics, precision engineering enhances the general fine and performance of post hole digger gear reducers, making sure that they operate appropriately and reliably in traumatic agricultural and creation environments.

.jpg?imageView2/2/format/jp2)

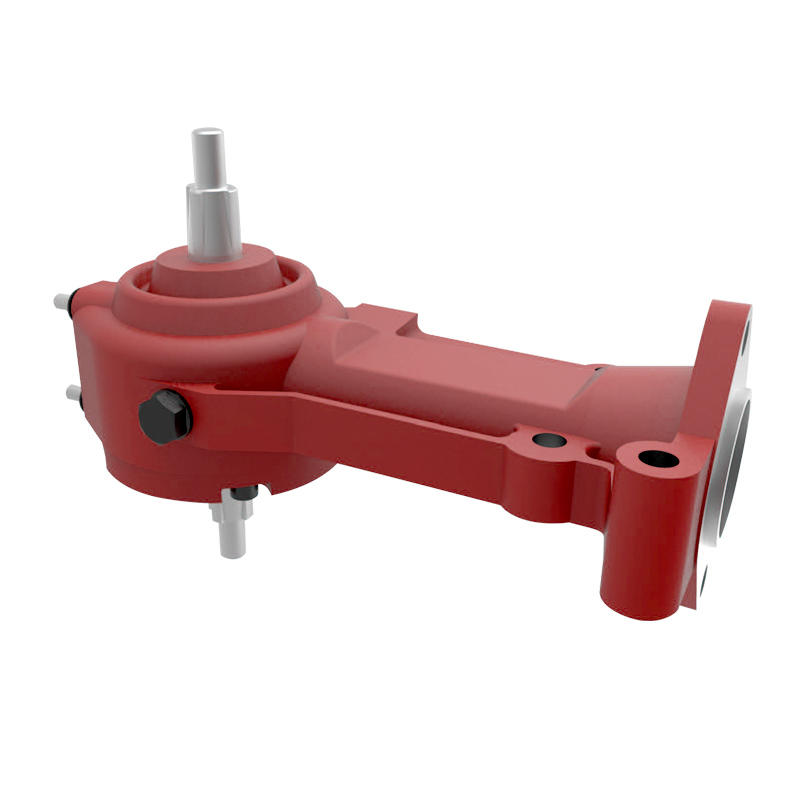

GEARBOX RM16

English

English 中文简体

中文简体 Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)