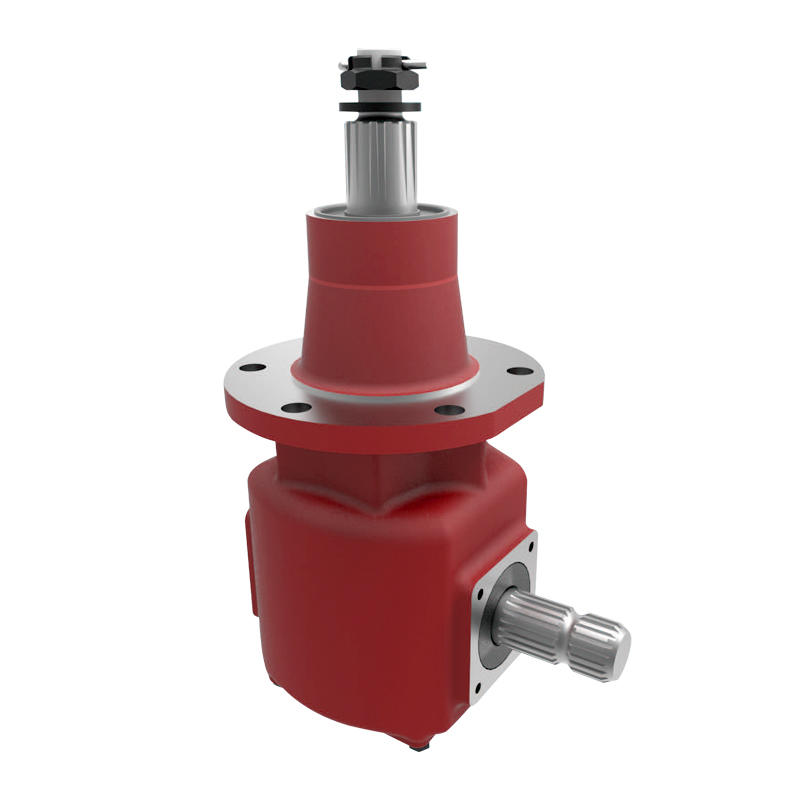

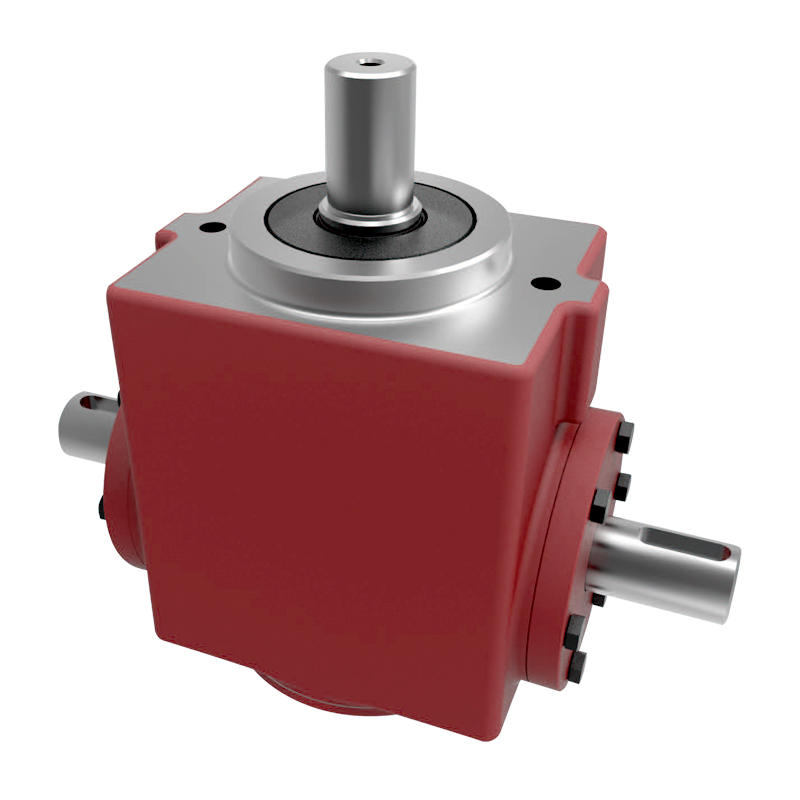

Combine harvesters are invaluable machines in modern agriculture, revolutionizing the process of crop harvesting. A key component within these machines is the Combine Harvester Gearbox, which plays a pivotal role in determining the harvester's overall performance and adaptability in different crop conditions.

Before delving into the impact of gearbox selection, it's essential to grasp the fundamental functions of Combine Harvester Gearboxes:

1. Power Transmission: Combine Harvester Gearboxes are responsible for transmitting power from the engine to various components of the harvester, such as the threshing mechanism, cutting platform, and grain handling systems.

2. Speed Control: They allow operators to control the rotational speed of different harvester components, enabling adjustments for different crop types and conditions.

3. Torque Amplification: Combine Harvester Gearboxes can amplify the torque generated by the engine, providing the necessary force to cut and thresh crops effectively.

4. Direction Control: Many gearboxes enable the harvester to operate in both forward and reverse directions, facilitating precise maneuvering and minimizing crop damage.

Now, let's explore how the choice of Combine Harvester Gearbox influences performance in various crop conditions.

1. Wheat and Barley Harvesting:

Combine harvesters are commonly used for wheat and barley harvesting, where efficiency and clean grain separation are essential. In such conditions, the selection of a gearbox with precise speed control and gentle threshing mechanisms is crucial. Agricultural Harvester Gearboxes designed for cereal crops excel in maintaining grain quality by preventing excessive damage during the threshing process.

2. Corn Harvesting:

Corn harvesting involves unique challenges due to the presence of husks and cobs. In this context, Combine Harvester Gearboxes with specialized settings for corn are preferred. These gearboxes often feature adjustable concave settings and rotor speeds, allowing for efficient husk removal and kernel retention.

3. Soybean and Canola Harvesting:

Soybeans and canola have delicate pods that can shatter easily if not handled carefully. The gearbox choice plays a critical role in minimizing pod shatter and preserving crop yield. Gearboxes with adjustable rotor speeds and concave settings are crucial for gentle crop handling in these conditions.

4. Rice Harvesting:

Rice is typically grown in flooded fields, posing unique challenges for combine harvesters. The choice of a gearbox that can withstand water exposure and resist corrosion is essential. Additionally, specialized gearboxes for rice often have features for preventing grain loss in wet conditions.

5. Variable Crop Conditions:

In regions where multiple crops are grown in rotation, the adaptability of the Combine Harvester Gearbox becomes paramount. Gearboxes with quick and easy adjustment mechanisms for changing crop conditions enable operators to transition smoothly between different harvesting tasks.

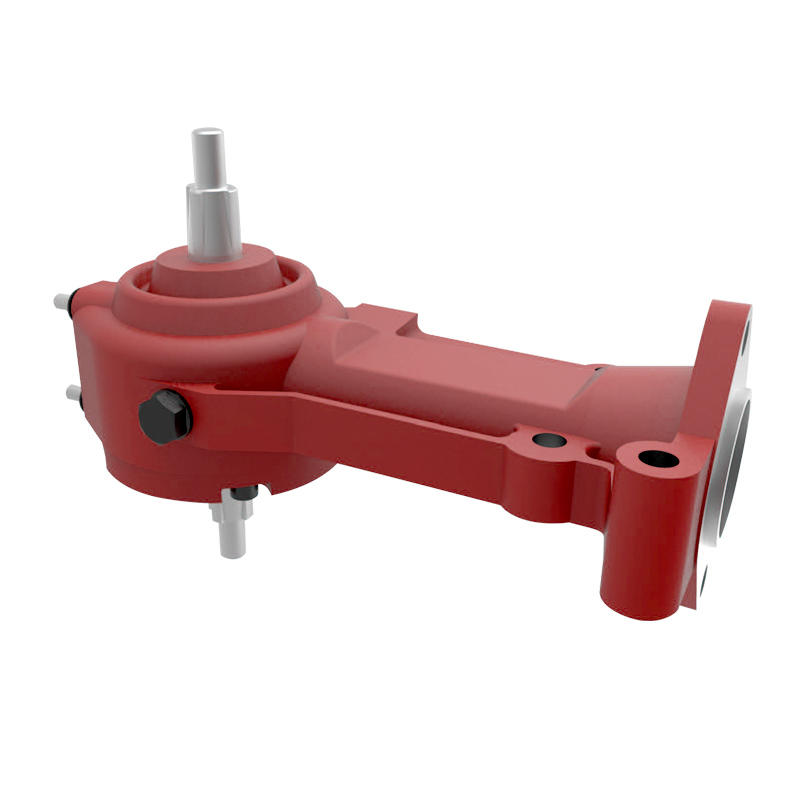

6. Compactness and Maneuverability:

In orchards or vineyards, where space is limited, compact Combine Harvester Gearboxes are preferred. These gearboxes allow for easy maneuvering among rows of fruit-bearing trees or vines, making them essential for harvesting fruits like apples, grapes, and citrus.

7. Weed-Infested Fields:

In fields plagued by weeds, the gearbox's ability to handle tough and fibrous vegetation is vital. Agricultural Harvester Gearboxes designed for such conditions often feature reinforced components and additional safety measures to prevent damage from debris.

8. Maintenance and Reliability:

Regardless of the crop type, reliable performance is critical. Combine Harvester Gearboxes must be regularly maintained to ensure optimal operation. Choosing a gearbox with easy access to service points and robust construction can reduce downtime and maintenance costs.

9. Future Adaptability:

Given the evolving nature of agriculture, it's essential to select a Combine Harvester Gearbox that allows for future adaptability. This includes gearboxes with upgrade options or compatibility with precision farming technologies for improved efficiency and yield monitoring.

The choice of Combine Harvester Gearbox significantly influences the performance and adaptability of the harvester in various crop conditions. Agricultural Harvester Gearboxes tailored to specific crops or designed for flexibility in changing conditions enhance efficiency, minimize crop loss, and contribute to sustainable and productive farming practices.

English

English 中文简体

中文简体 Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)