Home / News / Industry News / Here are a few characteristics that contribute to the benefit of preservation in agricultural manure spreader gearboxes

Easy upkeep capabilities in agricultural manure spreader gearboxes are crucial for making sure that farmers and equipment operators can perform recurring renovation with minimal problem. Here are a few characteristics that contribute to the benefit of preservation in agricultural manure spreader gearboxes:

Accessible Lubrication Points: Manufacturers layout gearboxes with easily reachable lubrication factors, allowing operators to efficiently grease or oil the components that require ordinary lubrication. This accessibility simplifies the lubrication manner and promotes constant preservation.

Quick-Release Mechanisms: Some manure spreader gearboxes contain brief-launch mechanisms for unique components. This can encompass hatches or doorways that provide easy get entry to to internal elements, facilitating short inspections, cleaning, and renovation with out the need for huge disassembly.

Clear Maintenance Instructions: Gearbox manufacturers frequently offer clean and complete maintenance commands in person manuals. These commands guide operators thru habitual responsibilities which includes lubrication schedules, inspection factors, and troubleshooting processes.

User-Friendly Design: The average layout of the gearbox considers ease of maintenance. This may involve the strategic placement of additives, minimizing the need for huge disassembly whilst having access to vital parts.

Tool-Free Maintenance: In some instances, manufacturers layout gearboxes with components that may be maintained or replaced with out the want for specialised tools. Tool-unfastened renovation functions beautify the convenience and velocity of ordinary tasks.

Replaceable Wear Parts: Wear components, which includes seals and bearings, may be designed to be without difficulty replaceable. This simplifies the renovation technique, permitting operators to change out worn components fast and efficaciously, minimizing downtime.

Diagnostic Features: Modern manure spreader gearboxes can also include diagnostic capabilities, which includes sensors or indicators, to alert operators to capacity issues. This early warning machine can help save you extra large issues and simplify troubleshooting.

Corrosion-Resistant Materials: The use of corrosion-resistant materials in crucial components reduces the probability of rust and corrosion. This not best contributes to the longevity of the gearbox however also makes maintenance responsibilities less hard.

Modular Construction: Some gearboxes have a modular production, that means they consist of awesome additives that may be without difficulty removed and changed. This modularity simplifies upkeep and protection, as operators can address unique problems without having to disassemble the complete gearbox.

Sealed Bearings and Components: Sealed bearings and different important additives assist defend the gearbox from contaminants. Seals save you dirt, dust, and moisture from coming into sensitive areas, decreasing the hazard of premature put on and extending the intervals between preservation duties.

User Support and Training: Manufacturers may provide schooling or support offerings to teach operators on right preservation tactics. This guarantees that operators have the information and talents needed to carry out renovation duties effectively.

By incorporating those smooth upkeep features, agricultural manure spreader gearboxes goal to reduce downtime, simplify protection, and enlarge the general lifespan of the equipment. Regular and easy renovation practices make contributions to the most fulfilling performance of manure spreaders within the subject.

.jpg?imageView2/2/format/jp2)

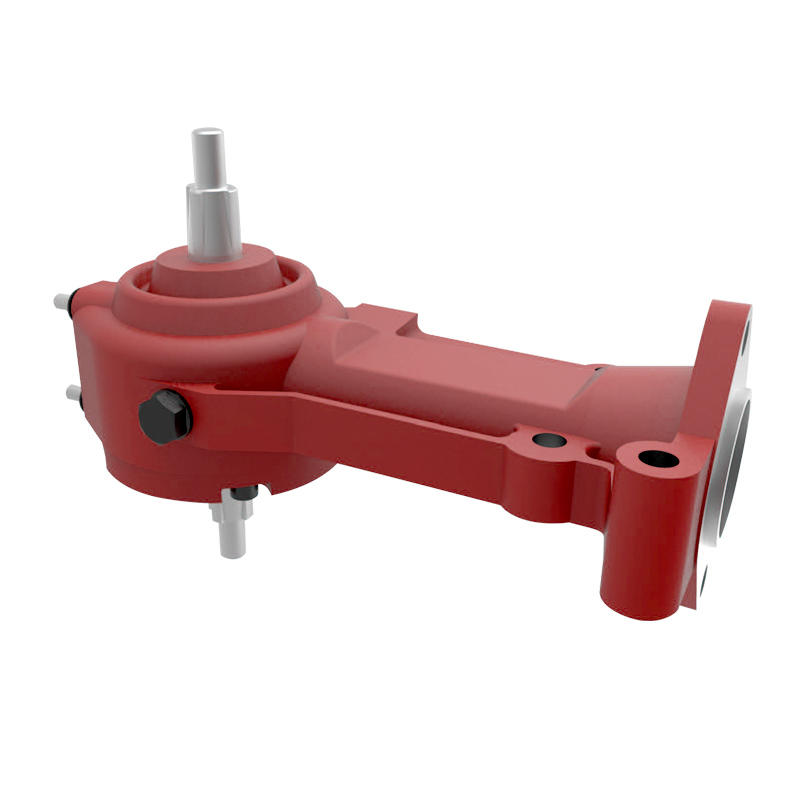

GEARBOX RM08

English

English 中文简体

中文简体 Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)