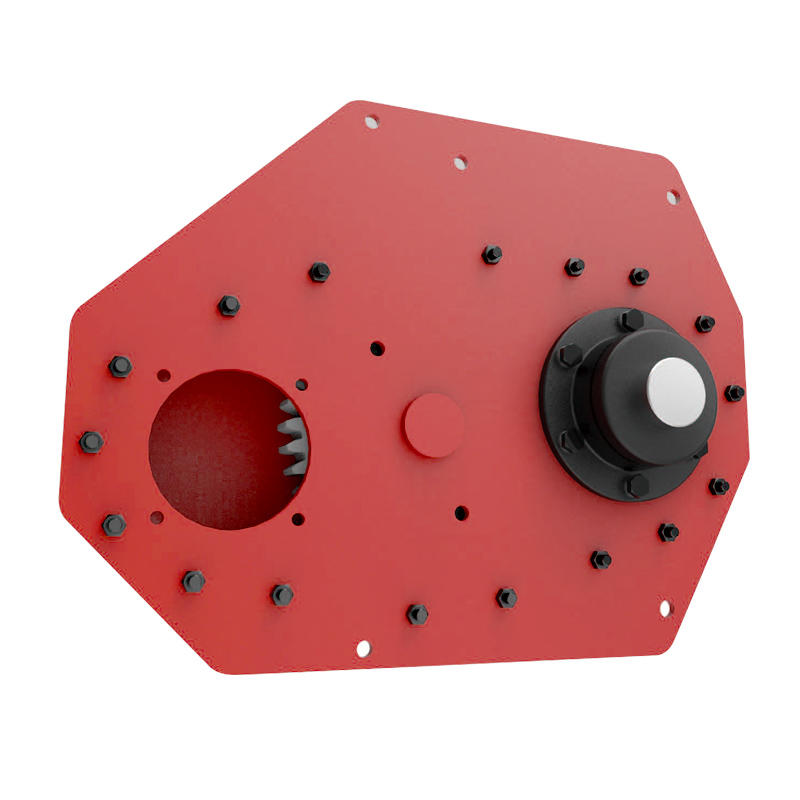

Feed mixers are crucial in modern livestock and poultry farming, ensuring that animals receive the right nutrition. Central to the operation of these machines are the feed mixer gearboxes, which play a critical role in blending various feed ingredients. To maintain the reliability and longevity of feed mixer gearboxes, it is essential to implement a proactive maintenance regimen. Here are some aspects:

1. Visual Inspection: Conduct routine visual inspections to check for any signs of wear, damage, or oil leaks on the gearbox housing. Inspect the gearbox's exterior for loose bolts, misalignment, or other abnormalities.

2. Oil Level Check: Monitor the gearbox's oil level regularly. Ensure that the oil level is within the recommended range as specified in the gearbox manufacturer's manual. Low oil levels can lead to overheating and premature wear.

3. Lubrication Schedule: Adhere to a proper lubrication schedule recommended by the gearbox manufacturer. Use high-quality lubricants suitable for the specific gearbox model. Regularly replace the gearbox oil as per the maintenance schedule.

4. Oil Quality: Ensure that the gearbox oil remains clean and free of contaminants. Contaminated oil can accelerate wear and damage internal components. Regularly inspect the oil for discolouration or foreign particles and change it if necessary.

5. Alignment Check: Ensure that the gearbox is properly aligned with the drive and mixer components. Misalignment can cause excessive load on the gearbox and lead to premature failure. Correct any misalignment issues promptly.

6. Load Distribution: Pay attention to the load distribution on the gearbox. Overloading can stress the gearbox and reduce its lifespan. Follow the manufacturer's guidelines for maximum load capacities.

7. Seal Inspection: Examine the seals and gaskets on the gearbox for signs of wear, cracking, or leakage. Damaged seals can allow contaminants to enter the gearbox, leading to damage. Replace worn seals promptly.

8. Vibration Analysis: Use vibration analysis tools to monitor the gearbox's vibration levels. Excessive vibration can indicate problems such as misalignment or internal damage. Address any abnormal vibration promptly.

9. Noise Evaluation: Unusual noises, such as grinding or whining sounds, can be indicative of internal gearbox issues. Investigate and diagnose the source of the noise and take corrective action as needed.

10. Temperature Checks: Regularly measure the operating temperature of the gearbox during operation. Elevated temperatures can indicate issues like inadequate lubrication or overloading. Investigate and rectify the cause of overheating promptly.

11. Scheduled Maintenance: Establish a preventive maintenance schedule for the entire feed mixer, including the gearbox. Follow the manufacturer's recommendations for maintenance intervals and procedures.

12.Documentation: Maintain detailed records of all maintenance activities, including dates, oil changes, inspections, and any repairs or replacements. Documentation helps track the gearbox's history and aids in troubleshooting.

13. Expert Inspection: Periodically engage a qualified technician or gearbox specialist to conduct a thorough inspection of the feed mixer gearbox. Their expertise can uncover potential issues early and prevent costly breakdowns.

Proper maintenance of feed mixer gearboxes is vital to ensure their long-term reliability and performance. Regular inspections, lubrication, alignment checks, and proactive measures are essential to prevent unexpected downtime and costly repairs. I hope these suggestions above can inspire you.

English

English 中文简体

中文简体 Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)