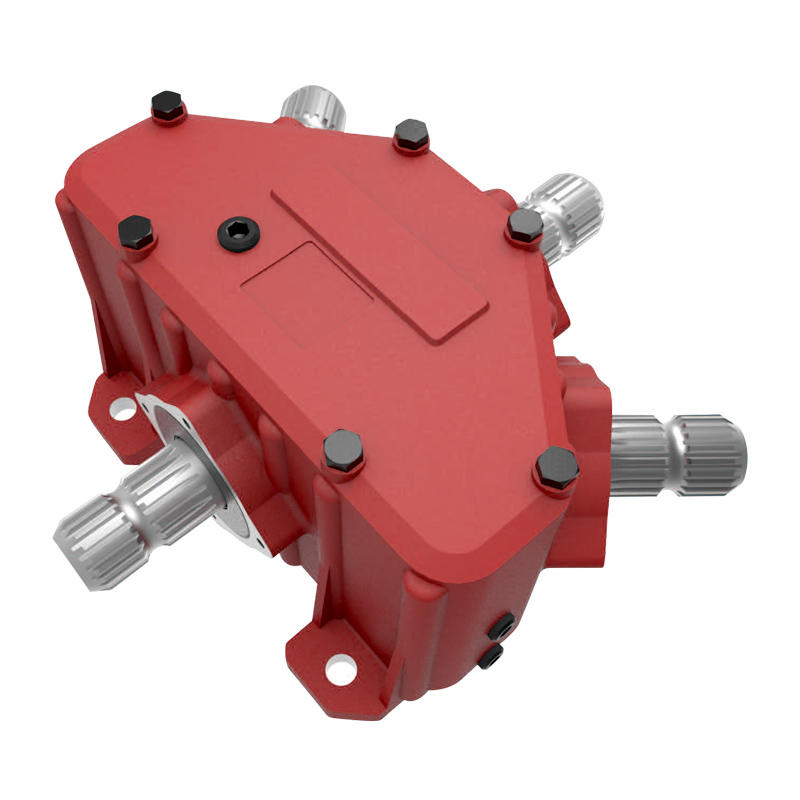

Rotary cutter gearboxes are at the heart of a wide range of agricultural and industrial equipment used for cutting and shredding vegetation, crops, and other materials. These gearboxes play a pivotal role in ensuring the efficiency, precision, and durability of rotary cutters, flail mowers, and similar equipment.

1. Rotary Cutter Gearboxes Overview:

Rotary cutter gearboxes, often referred to as mower gearboxes or flail mower gearboxes, are power transmission components designed to connect a tractor's power source (typically the PTO - Power Take-Off) to the cutting mechanism of rotary cutters or flail mowers. These gearboxes are responsible for converting the rotational motion from the tractor into the necessary cutting power.

2. Improved Power Transmission:

One of the most significant advancements in rotary cutter gearboxes is improved power transmission efficiency. Modern gearboxes are designed to minimize power losses during transmission, ensuring that more of the tractor's power is utilized for cutting. This results in faster, more efficient cutting operations, reducing fuel consumption and increasing productivity.

3. Enhanced Durability:

Rotary cutter gearboxes are exposed to harsh environmental conditions and heavy workloads. Recent innovations have focused on increasing the durability and lifespan of these components. Manufacturers use high-quality materials and advanced manufacturing techniques to build gearboxes that can withstand the rigors of tough cutting tasks.

4. Variable Speed Control:

Innovations in rotary cutter gearboxes have led to the integration of variable speed control features. This allows operators to adjust the rotational speed of the cutting mechanism to match the specific requirements of the task and the type of material being cut. Variable speed control enhances precision and adaptability in different cutting situations.

5. Reverse Rotation Capability:

Many modern rotary cutter gearboxes offer reverse rotation capabilities. This feature is particularly valuable when dealing with obstacles or clearing debris. Being able to switch the cutting direction quickly enhances safety and efficiency during cutting operations.

6. Safety Measures:

Safety is a paramount concern when working with rotary cutters and flail mowers. Recent innovations in gearbox design include safety features like shear pins or clutches that protect the gearbox from damage when the cutting mechanism encounters an obstacle. These safety measures help prevent costly repairs and downtime.

7. Reduced Maintenance:

Maintenance is a critical aspect of gearbox performance. Newer rotary cutter gearboxes are designed with user-friendly maintenance in mind. They often feature easy access to lubrication points and wear parts, reducing downtime and simplifying upkeep.

8. Compatibility and Adaptability:

Rotary cutter gearboxes are used in a variety of cutting equipment, from rotary cutters to flail mowers. Innovations have focused on ensuring compatibility and adaptability. This means that a single gearbox can often be used with different cutting implements, providing cost-effective versatility for equipment owners.

9. Flail Mower Gearboxes:

Flail mowers are specialized cutting machines known for their versatility and ability to handle tough vegetation. Flail mower gearboxes are designed to meet the specific requirements of these machines. Innovations in flail mower gearbox design include reinforced components, adjustable cutting heights, and improved debris management systems.

10. Eco-Friendly Design:

In response to increasing environmental concerns, some manufacturers have developed eco-friendly gearbox designs. These gearboxes incorporate features like reduced noise emissions and improved fuel efficiency, contributing to a more sustainable and environmentally conscious approach to cutting.

11. Remote Monitoring and Automation:

Advancements in technology have enabled the integration of remote monitoring and automation features in rotary cutter gearboxes. Operators can now monitor gearbox performance, temperature, and maintenance needs remotely, allowing for proactive maintenance and reducing the risk of breakdowns.

12. Precision Agriculture Integration:

The agricultural industry is increasingly adopting precision agriculture practices. Rotary cutter gearboxes are no exception. Some gearboxes now feature compatibility with precision agriculture systems, enabling operators to implement precise cutting patterns and optimize field management.

Rotary cutter gearboxes, whether used in rotary cutters or flail mowers, have evolved significantly due to ongoing innovations. These advancements have led to improved power transmission, enhanced durability, variable speed control, and a range of safety features.

As the agriculture and cutting industries continue to evolve, the role of rotary cutter gearboxes remains central in ensuring efficient, precise, and environmentally conscious cutting operations.

English

English 中文简体

中文简体 Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)