In modern agriculture and animal husbandry, the efficient and consistent mixing of animal feed is crucial to ensure the health and productivity of livestock. The core components responsible for this task are the Feed Mixer Gearbox and Feed Mixer Drives. These vital components play a pivotal role in achieving the delicate balance between power and efficiency in the feed mixing process.

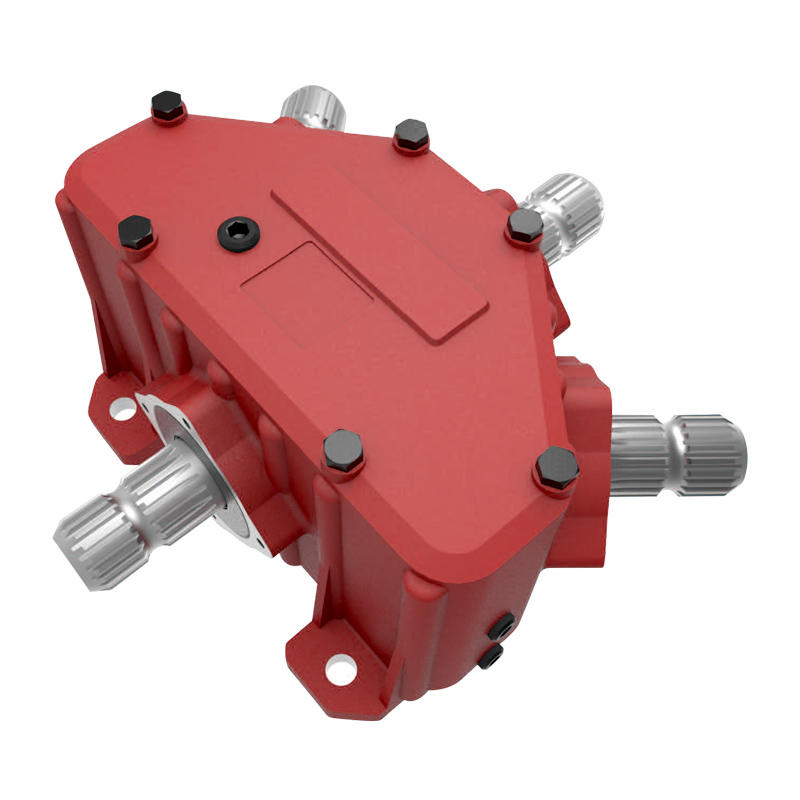

Feed Mixer Gearbox:

The Feed Mixer Gearbox is the heart of the feed mixing equipment, responsible for transmitting power from the prime mover (typically an electric motor or an internal combustion engine) to the mixing auger. It's designed to efficiently blend various ingredients, such as grains, supplements, and additives, to create a uniform and nutritionally balanced feed.

1. Power Transmission: Feed Mixer Gearboxes are engineered to transmit power effectively from the source to the mixing auger. They ensure that the mixing process is consistent and that the feed ingredients are thoroughly combined.

2. Torque and Speed Control: These gearboxes offer control over both torque and speed. Operators can adjust these parameters to match the specific requirements of the feed mixture, allowing for precise blending regardless of the ingredients' density or size.

3. Durability: In the demanding agricultural environment, durability is paramount. Feed Mixer Gearboxes are constructed to withstand the rigors of continuous operation, including the abrasion caused by abrasive feed components.

4. Efficiency: Achieving the right balance between power and efficiency is crucial. These gearboxes are designed to maximize the efficiency of the mixing process, reducing energy consumption while maintaining optimal performance.

5. Maintenance: Routine maintenance is essential to ensure the long-term reliability of Feed Mixer Gearboxes. Many models are designed for ease of maintenance, with accessible lubrication points and wear parts.

Feed Mixer Drives:

Feed Mixer Drives encompass the various technologies and systems used to power feed mixers. They provide the necessary energy to drive the mixer gearbox and, in turn, the auger. Innovations in feed mixer drives have significantly improved the efficiency and flexibility of feed mixing operations.

1. Electric Drives: Electric drives have gained popularity due to their energy efficiency and precision. They offer variable speed control, allowing for fine-tuned adjustments to the mixing process. Additionally, electric drives often have lower maintenance requirements compared to mechanical counterparts.

2. Hydraulic Drives: Hydraulic drives remain a viable option for feed mixers, especially in situations where a hydraulic power source is readily available. They provide robust and consistent power delivery, ensuring reliable mixing.

3. PTO (Power Take-Off) Drives: Tractors equipped with PTOs can power feed mixers through PTO drives. While versatile, these drives may have limitations in terms of speed control and efficiency compared to electric or hydraulic options.

4. Precision Control: Recent innovations in feed mixer drives have introduced advanced control systems. These systems may incorporate load sensors, automation, and even remote monitoring to optimize mixing operations and reduce human error.

Balancing Power and Efficiency:

The successful blending of animal feed requires striking a balance between power and efficiency:

- Power: Adequate power is necessary to ensure that even the most challenging feed ingredients, such as coarse fibrous materials or compacted grains, are thoroughly mixed. Feed Mixer Gearboxes, with their torque capabilities, provide the power needed for consistent results.

- Efficiency: Efficiency is crucial for minimizing energy consumption and reducing operational costs. Modern Feed Mixer Drives, especially electric drives, offer precise speed control and energy-efficient operation, enhancing the overall efficiency of feed mixing.

- Consistency: Achieving a consistent mixture ensures that each batch of feed provides uniform nutrition to the livestock. Properly selected and maintained gearboxes and drives contribute to this consistency.

- Flexibility: The ability to adapt to different feed recipes and ingredient types is vital in modern animal farming. Innovations in feed mixer drives provide the flexibility to adjust mixing parameters as needed.

- Maintenance: Reducing downtime due to maintenance is essential for operational efficiency. Gearboxes and drives designed for easy maintenance help ensure that the equipment remains in optimal condition.

The Feed Mixer Gearbox and Feed Mixer Drives are integral components in achieving the delicate balance between power and efficiency in feed mixing operations.

English

English 中文简体

中文简体 Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)